Our KM Tamper

Our KM Tamper

We tamp a lot. From now on, with our own tamper. Our KM Tamper was specially developed according to the requirements and wishes of our barista team and guarantees precise compaction of the coffee grounds. For perfect, even extractions with every espresso. Manufactured with the utmost precision in the Ruhr region – 100% Made in Germany .

Product features:

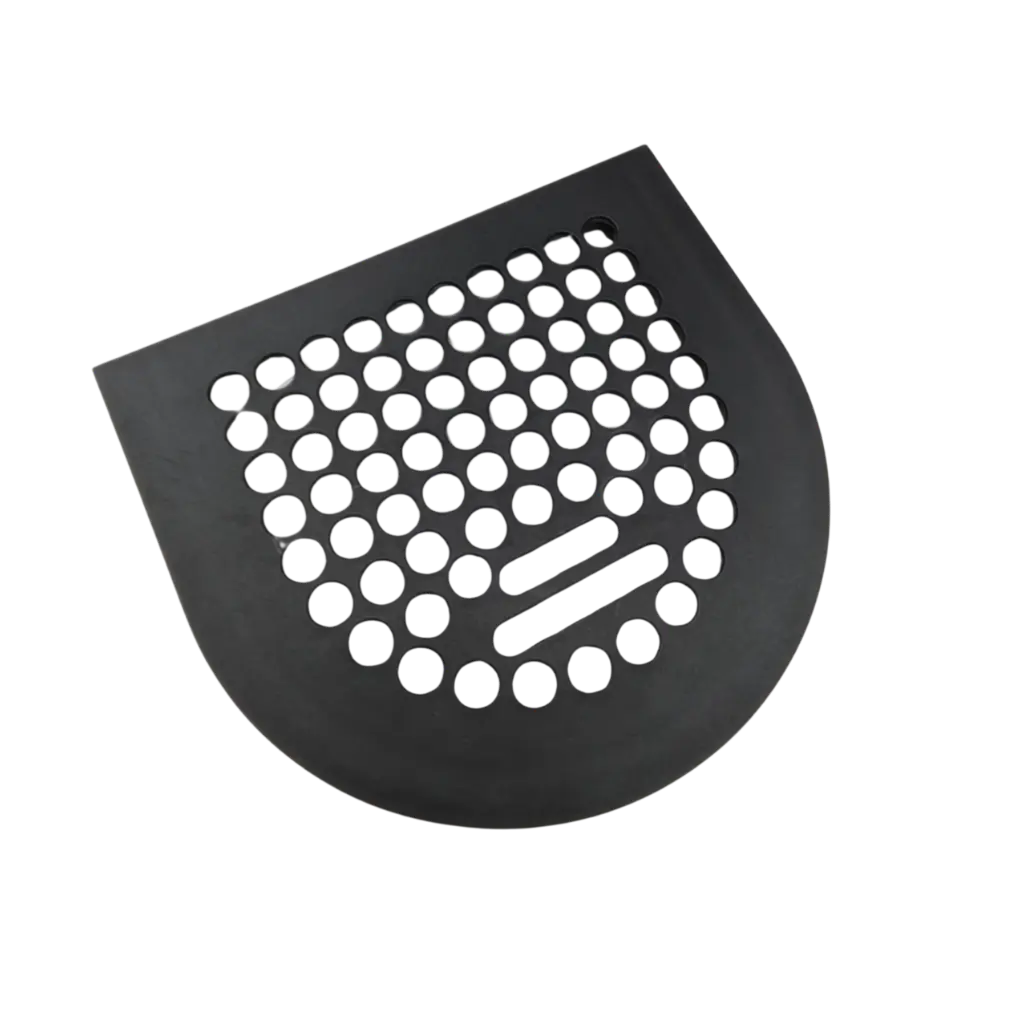

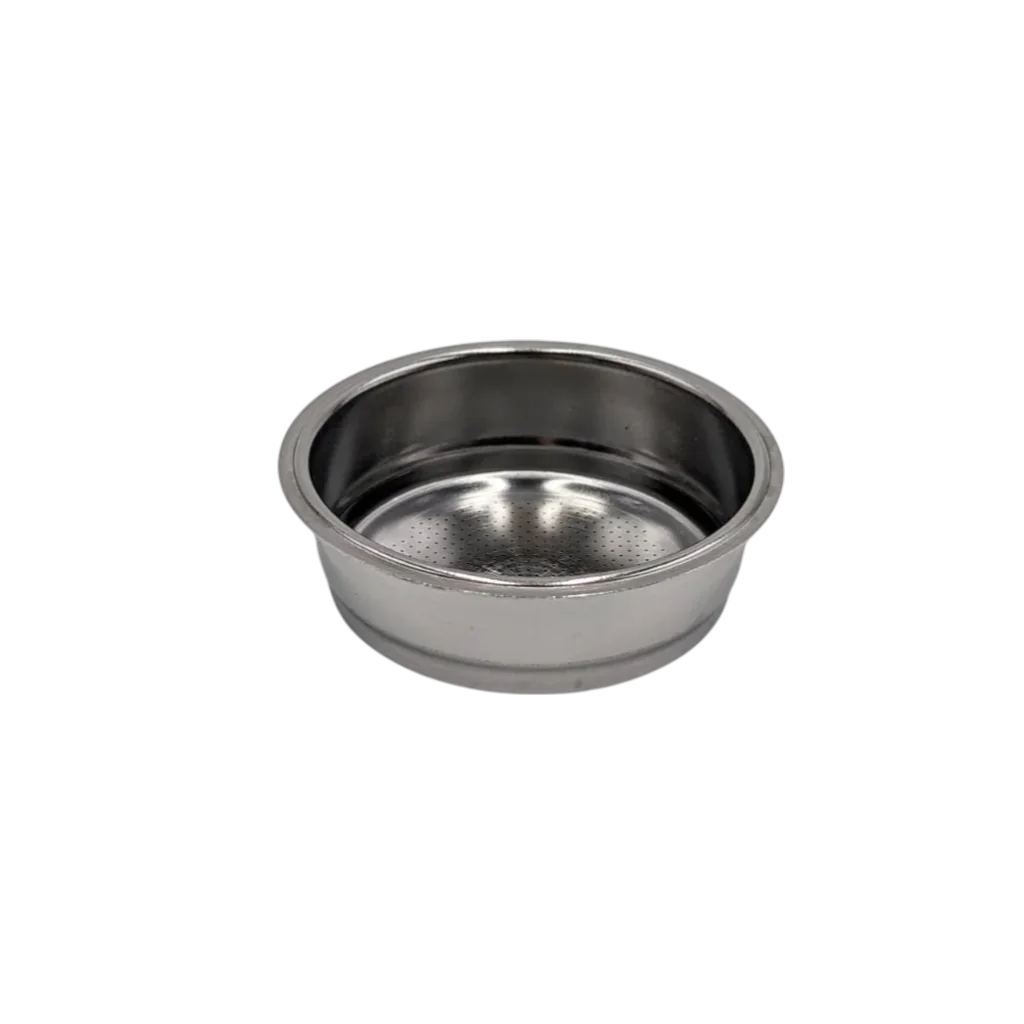

- Diameter: 58.5 mm The ideal diameter for all standard 58 mm sieves , both precision sieves and conventional espresso machine sieves. The tamper seals perfectly and ensures even compression right up to the rim, minimizing the risk of channeling and enabling better extraction.

- Material: The base of the tamper is made of stainless steel (1.4301) , a material known for its durability and food safety. It is widely used in the food industry, for example, for drinking containers and eating utensils.

- Innovative design: The convex recess in the base prevents the formation of a vacuum, protecting the coffee puck during extraction and preventing clumping. The design ensures that the tamper sits flush with the sieve, allowing for straight tamping.

- Individual wooden handles: Each wooden handle is unique, with slight variations in color due to its natural nature . Small hairline cracks in the wood are professionally sealed and do not constitute a defect.

- Surface treatment: The wooden handle is treated with a food-safe oil-wax combination that protects the wood, repels water, and simplifies maintenance. (EURO Standard 1186 Part 5/14).

- Scope of delivery: Tamper grip & tamper base.

Weight and dimensions:

- Weight: approx. 292 g

- Height: approx. 8.2 cm

- Handle diameter (widest point): approx. 3.8 cm

- Assembly: The tamper handle and the base can be easily unscrewed.

Care instructions:

- Wooden handle: To ensure longevity, do not clean the wooden handle in the dishwasher. Use a slightly damp microfiber cloth . Avoid harsh cleaning agents and standing water.

- Surface care: Treat the wooden handle regularly with food-safe hard wax oil and polish it with a microfiber cloth after it has dried.

- Stainless steel base: Can be easily cleaned in the dishwasher or wiped with a damp cloth.

Sustainability and local production:

Our KM Tamper is produced locally and in a resource-efficient manner . The handle is manufactured in Lüdinghausen, and the metal base is made in Hünxe—just 4 km from our coffee maker. This way, we support local artisan businesses and avoid unnecessary transport routes.

The manufacturing process:

- Base: Precision manufactured in Tobi Zimmer's workshop at the family-run Zimmer Maschinenbau on modern CNC lathes.

- Handle: Handmade in Elke Brandt 's workshop in a multi-step process including CNC milling, sanding, and turning.

Why the KM Tamper?

At Kaffeemacher:innen, we understand the challenges associated with conventional tampers. After years of testing in our Basel cafés and working with our baristas, including German Barista Champion Felix and two-time Swiss Champion Philipp, we decided to develop our own tamper that:

- Well thought out and functional and incorporates our accumulated experience and requirements.

- Produced locally and sustainably to minimize the ecological footprint.

- Aesthetically appealing and of high quality, it is a highlight in every kitchen.

Manufacturer:

Responsible person:

Guaranteed origin

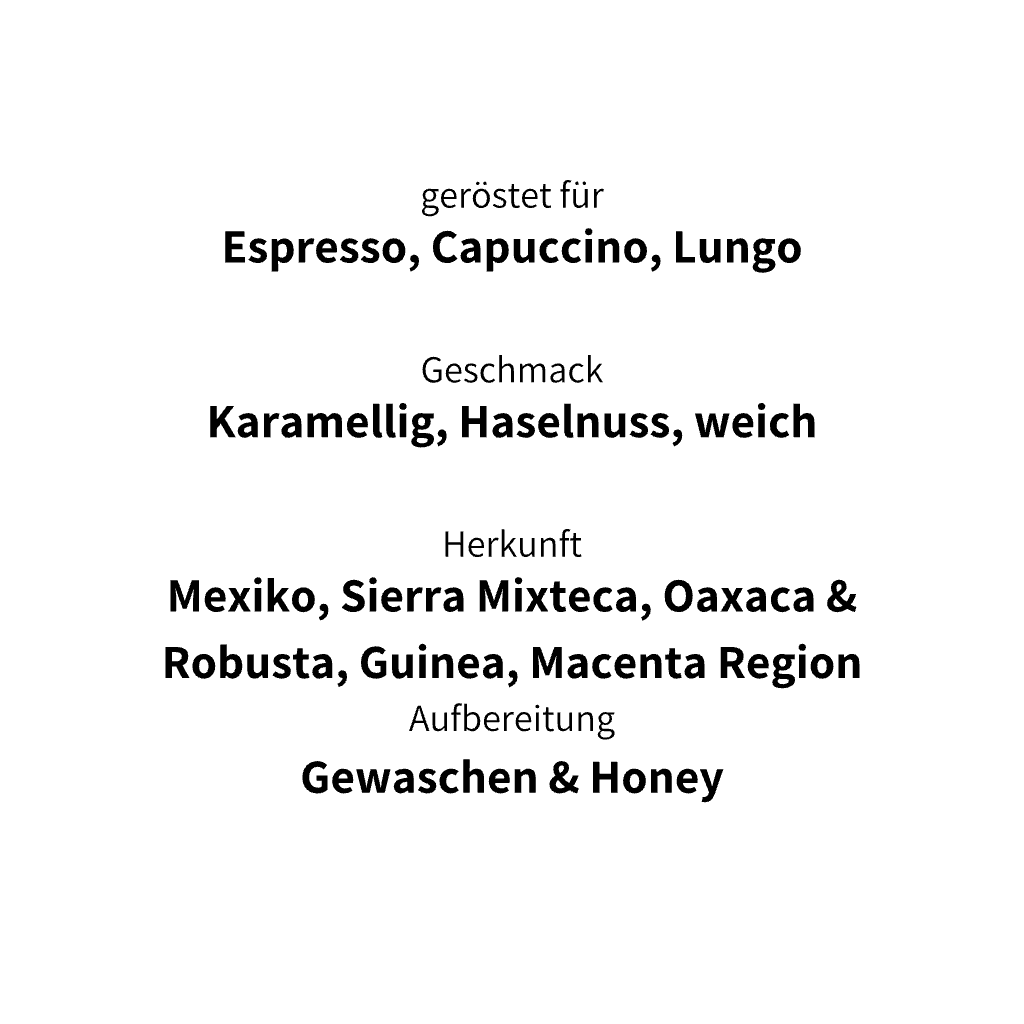

We know exactly where our coffee comes from and when and where it was roasted.

Free shipping from 75 €

Personal advice

We are here to help you with any questions or problems.

Fast shipping

Delivery from Germany or Switzerland