The E61 brewing group is ubiquitous in the world of traditional espresso machines. From ECM to Rocket to Lelit, all manufacturers use this technology that's over 60 years old. It has evolved over the years, but at its core, it has remained the same. But how does the Faema E61 system, revolutionized by Ernesto Valente, work?

E61 brewing group and thermosyphon principle

The E61's brewing group is a hallmark of machines that rely on proven technology. In addition to the striking group, the thermosyphon's circulating heating system is largely responsible for the stability of the technology.

The thermosyphon circulates the brewing water through the heat exchanger or boiler in a continuous flow through the brewing group. From there, it flows back into the boiler or heat exchanger, is further heated, and flows back into the brewing group. The brewing group itself weighs between 4 and 6 kilograms and is heated by the circulating water. This is why heating up brewing groups using the Faema E61 principle takes at least 25 minutes. The entire material must first be heated by the water.

On the one hand, this is ingenious, as it doesn't require a separate heater like other brewing groups. Once heated, the E61 brewing group's thermal stability is very high. On the other hand, the E61 principle makes espresso machines sluggish and very energy-intensive.

This sluggishness becomes apparent when adjusting the brewing temperature on PID-controlled machines. A lot of water must be flushed or a longer wait is required before the adjustment is reflected in the brewing group.

In addition, the system overheats if left unused for an extended period. Therefore, rinsing before brewing is very important to remove overheated water from the brewing group. To do this, rinse for 2-3 seconds before inserting the portafilter. The escaping water should no longer steam or spray when brewing begins. Overheating is more pronounced with E61 brewing groups with dual circuits.

Three valves and functions

The Faema E61 brewing group features three valves that perform important functions in the brewing process. The inlet valve is responsible for allowing water into the brewing group. The pre-infusion valve allows for pre-wetting of the coffee, which can promote a more even extraction. The drain valve, on the other hand, ensures that the pressure is released after the brewing process, allowing the portafilter to be removed and cleaned easily.

Cleaning the E61 brewing group

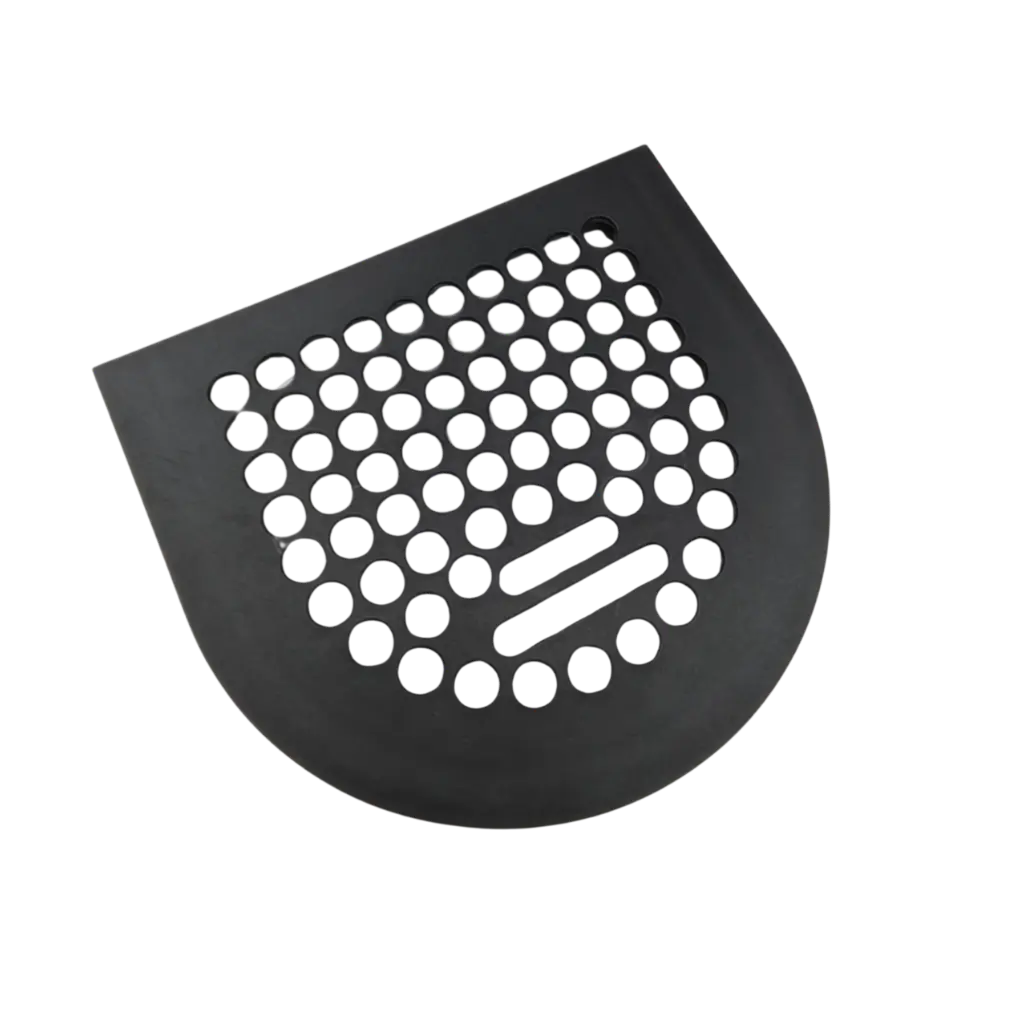

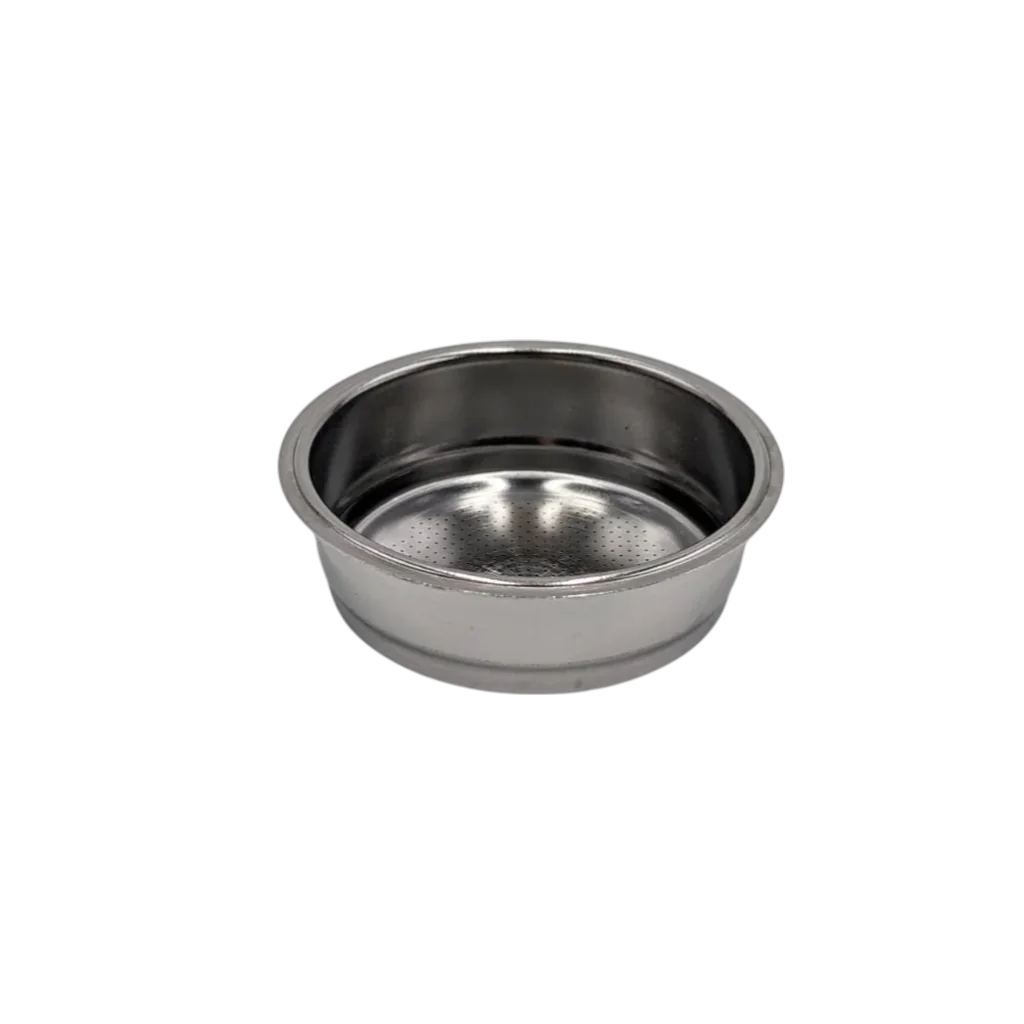

The E61 brewing group can be cleaned using the backflushing method. We've explained exactly how this cleaning process works here.

To do this, cleaning powder is poured into a blind sieve, the brewing process is started, and the cleaning powder is drawn into the area where residual coffee residue accumulates after extraction. This also makes it easy to clean the group's shower.

To really clean a shower, it should also be regularly pried down with a spoon or blind strainer to remove the stubborn pressure that collects underneath.

We recommend cleaning the brewing group once a week by applying pressure 5-10 times with cleaning powder for about two to three seconds.

Energy-intensive E61 technology

The slow heat-up time of over 25 minutes and the combination of large boilers make the Faema E61 technology extremely inefficient in terms of energy use . The large amount of water, often more than a liter, must be heated to heat the massive brewing group. When compared to the extraction of a double espresso with approximately 45 milliliters, it becomes clear that this cannot be efficient.

On the other hand, a well-heated espresso machine with an insulated boiler and warmed brewing group maintains the temperature relatively well.

Nevertheless, the energy balance remains problematic. We find the E61 brewing group in single-circuit, dual-circuit, and dual-boiler espresso machines. Brewing a double espresso with preheating consumes 2-6 times more energy than many modern thermoblock espresso machines.

Conclusion Faema E61 brewing group

The Faema E61 brewing unit seems outdated when compared to modern brewing units with fast heat-up times and low energy consumption. However, for many manufacturers, this brewing unit is still the first choice. This is thanks to its durability, easy maintenance, and cleaning. A brewing unit with a sixty-year history of success can hardly be wrong.

The most important pro argument, however, seems to be that many espresso enthusiasts have come to know the old technology as reliable and valuable, and when in doubt, they prefer to go with the tried-and-tested technology. This also leads manufacturers to prefer to rely on proven technology rather than experimenting.

However, as more and more manufacturers, both new and existing, are building faster, more energy-efficient, and more precise brewing groups using clever sensor and heating technology, the Faema E61's days are numbered in the medium term. While we will still see the E61 brewing group in coffee machines, its dominant position in the market has begun to crumble over the past three years.

Espresso machines with Faema E61 brewing group

Some examples of espresso machines with Faema E61 brewing group:

![]()