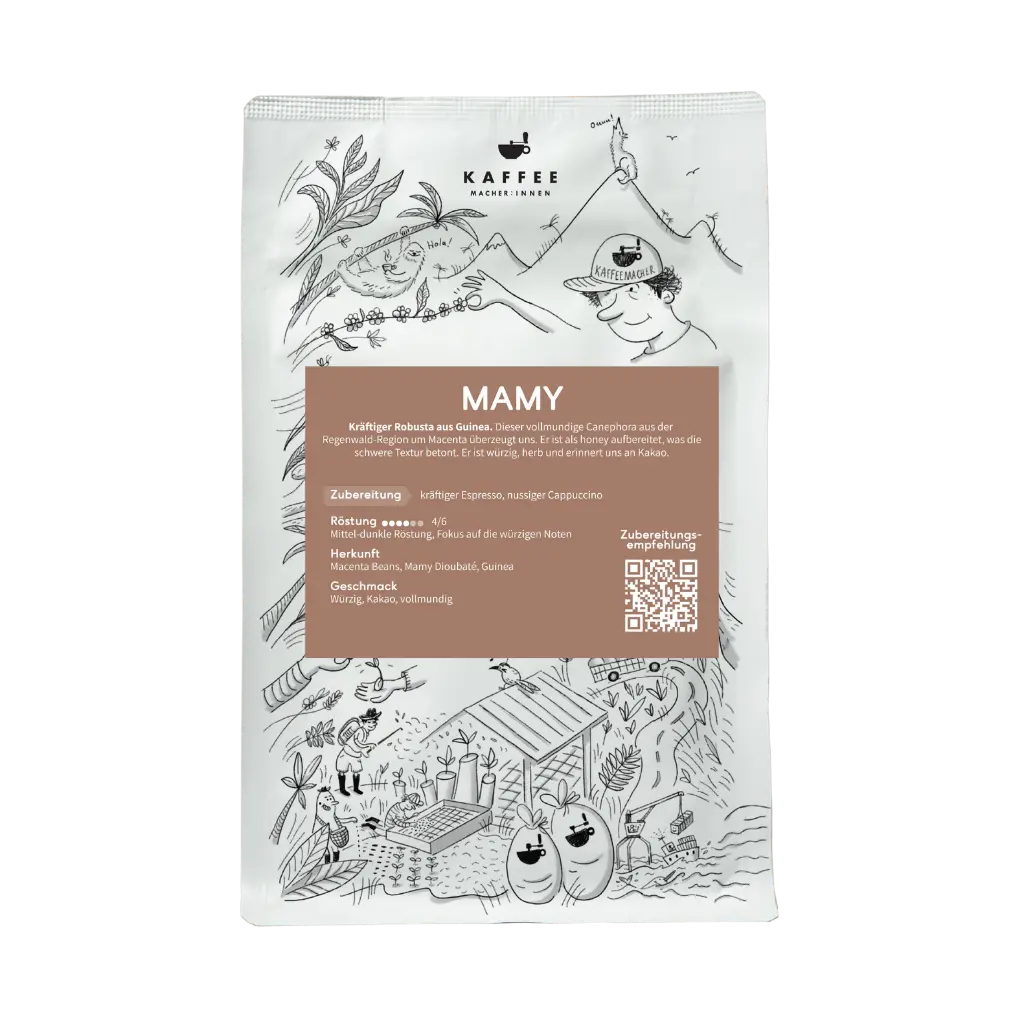

Why does coffee taste the way it does? Growing conditions and varieties are one part of the answer. The other is the role of fermentation in flavor development. How do washed coffees differ from honeys, naturals, and experimental fermentations in terms of taste? We'll define terminology and explain where flavors in coffee can come from.

"This coffee has notes of cherries and milk chocolate." Anyone who delves into coffee will eventually encounter increasingly precise descriptions of what the coffee might taste like. What was once a favorite discipline of specialty roasters is now also practiced by traditional and very large roasters.

A precise sensory description should help consumers gain a good impression of the coffee and sharpen their senses even before the first sip, allowing them to discover new or previously unnoticed flavors in the coffee. It's important to remember that every sensory impression is unique and shaped by one's own personal history.

When something tastes like an apple, we immediately conjure a mental image. Whether the apple is yellow, red, or green depends on our own experiences.

In coffee sensory science, we like to talk about a vocabulary that helps us express our impressions precisely. This vocabulary can be found, for example, in the SCAA's Flavor Wheel, created in 1995 and updated in 2016.

2016 version of the SCA Flavor Wheel

The 1995 version

In addition, the first study on a Canephora Flavor Wheel was published in early 2025.

The collection of descriptive words is diverse. The Flavor Wheel first groups aromas, before proceeding from the larger groups to the more detailed classification. While fruity and nutty notes have positive connotations, notes like petrol or medicinal can detract from the enjoyment.

The aroma wheel gives us a selection of aromas that can be tasted more or less frequently in coffee, regardless of whether they are positive or negative. But where do these aromas actually come from? And how do they get into the coffee?

This article consists of two parts.

Coffee processing / post-harvest process - clarification of terms and influence on coffee taste

If we imagine coffee as a puzzle, we notice countless smaller pieces that fit together harmoniously. This applies to both a perfectly brewed espresso and raw coffee.

Before sowing a coffee variety, it's important to consider whether the soil has the nutrients it needs. Also, whether the chosen variety will receive the degree of sun or shade it needs for balanced growth. And once coffee cherries are on the tree, the producer decides exactly when they will be picked—because red isn't always the same.

Like a traffic light, the color of the coffee cherry indicates whether it is ripe.

There are big differences in the type of red color, which can affect the taste of the coffee.

From the moment a cherry is picked, we speak of the post-harvest process, or processing . As soon as the cherry is separated from the stem, a small wound appears in the exocarp .

Bacteria and yeasts can now react and activate metabolism, the fruit begins to exchange oxygen, and the opening, with its sweet aroma, attracts insects, which in turn carry bacteria and yeast. Every stage the coffee cherry reaches potentially influences the quality and thus the final taste of the coffee.

The post-harvest process does not begin with the drying of the cherry, pulping or fermentation, but precisely when the cherry is separated from the stem.

In the following sections, we will explain what is important so that all the positive properties inherent in the coffee cherry result in a good taste.

Step 1: from the tree to further processing

The following points should be considered when separating the cherries from the stem

clean storage place

- What do we do with the picked cherries? Employees usually pick the cherries and place them in a cloth, a tied-around plastic bag, or a container made of raffia or similar material.

- Once the bag is full, transfer the cherries to a larger plastic bag. These bags quickly become a melting pot of insects, bacteria, sugars, and yeasts, which can trigger unwanted fermentation.

- The longer coffee cherries remain in the bags, the greater the risk that unwanted or off-flavors will develop in the first step after picking

- the bags must either be replaced or always washed well

Plastic bags containing pulped and washed coffee are placed on a tarp and not directly on the ground.

not too much weight, not too big bags

- Anyone who has ever witnessed a wine harvest may have seen that particularly valuable grapes are transported in a single layer in small, multi-tiered containers. This reduces the weight on the grapes, and they are not already crushed.

- Coffee cherries are much harder than grapes, but it can happen that the lowest cherries in the transport bag are already crushed

- These cherries should be sorted out before further processing to ensure the highest quality standards

Time until the next step

- The time until the next processing step is crucial

- the strategies and opinions differ widely here

- Globally valid literature still recommends pulping coffee cherries as quickly as possible in order not to “risk” fermentation - which makes it clear that for many, fermentation is unwanted and a source of danger rather than an opportunity for more aroma

- In fact, the time of intermediate storage of the cherries before the next processing step is decisive, depending on what is sought

-

Coffees that are mechanically degummed or depulped before treatment with water are often processed very quickly (on the same day)

-

We know, especially from Colombia, that producers treat coffee cherries with ozone to eliminate yeasts and bacteria on the surface. In subsequent processing steps, they work with the microorganisms found within the cherries or add starter cultures.

-

In many parts of Central America, the tradition of reposa exists, a storage of coffee cherries for several hours before they are processed further

-

In Nicaragua, for example, we rely on a 16-hour rest period for the cherries before further processing. In contrast to the control sample, which is processed immediately, we detect slightly more sweetness and acidity in the roasted coffee.

-

We have had this scientifically accompanied by the ZHaW: you can find the work below

Step 2: the agony of choice - to pulp or not to pulp?

Whether the coffee was placed in a reposa or whether the cherries were processed shortly after picking has no impact on the following steps. The next step is to decide what happens to the coffee cherries: is the pulp pressed away or left intact?

The quality of the picking and sorting plays a major role. If the majority of the cherries picked are semi-ripe, direct drying of the coffee cherries (so-called natural drying) is rarely the goal. The cherries contain too little sugar, which could provide new aromas during intensive fermentation. If the cherries are very ripe and uniformly sorted, all further processing steps are possible.

With all the further steps, an aroma can now be added to the coffee that would not have been there before.

Targeted fermentation creates aroma precursors, which are then converted into aromas during roasting.

A fundamental decision: to remove pulp or not?

Is the coffee cherry dried intact, or is the pulp (the so-called mesocarp ) removed? This decision not only determines the further procedure but also the intention for which aroma should be enhanced.

1. Remove all pulp: mechanical demucilagination

- Here we work with so-called demucilaginators or eco-pulpers

- large machines that not only expose the seed, but also remove the entire mucilage through friction and high-pressure water jets

- so there is no fermentation

- The coffee beans come out of the process as wet Pergamino after a few minutes and then go into drying as quickly as possible

*Especially at the peak of the harvest, when most coffee cherries are delivered for processing in a short time, the desmucilaginadores are the most reliable and efficient tool for processing the cherries

** No fermentation takes place during this processing , meaning no new aromas are created that are not already present in the coffee seeds as so-called aroma precursors. Depending on the sensory requirements, these coffees often have a somewhat austere flavor. Higher qualities often have a delicate, clean acidity. The texture depends on the ripeness of the cherries, as does the type of aroma. However, since these are often high-volume coffees, fewer uniform cherries end up in the processing, which limits the aromatic complexity of the coffee.

Many possibilities with the Demucilaginators

Due to their high efficiency and low water consumption, demucilaginators are now used worldwide. Newer generations of the devices allow the amount of mucilage to remain attached to the coffee bean to be precisely adjusted. Producers in Costa Rica, in particular, refined this technique in the 2000s and invented various types of honey.

2. Partially remove the pulp: pulp

- This involves working with either a despulpadora, a manual or mechanical – often petrol-driven – pulping machine

- Cherries fall into a hopper and are crushed by a rotating drum against a front plate, where the pulp is separated from the seeds

- Depending on the size of the cherries and the thickness of the pulp, adjustments must be made to the front plates so that the beans are pressed out of the cherries without damage

- the majority of the mucus (mucilage) remains attached to the semen

The despulpadoras are not designed to remove all the pulp and thus the mucilage, so the process of fermentation as a biological process (= releasing the mucilage) and washing has developed - more on this later.

3. Leave the cherry intact - the pulp stays on - Natural

- The oldest method of processing coffee after picking is drying in the coffee cherry

- the method is also known as natural processing

- In the most rudimentary version of this processing, the coffee cherry is laid out in a dry place until the seeds inside have a residual moisture content of approximately 12%

- In the now highly sophisticated methods, technical and biological tools are used to create ever more flavors that were not present before

- Natural processing produces the best and worst coffees I have ever tasted

The coffee world between the poles - all other types of processing

Until the turn of the millennium, the burning question in the post-harvest process was: to wash or not to wash? For decades, naturals were the way coffees were dried, but we're talking about a different level of precision than today. With increasing processing efficiency and new market demands, the 1970s saw a sharp rise in wet mills or beneficios, collection stations where coffee cherries were pulped and washed.

The ability to pulp and wash coffee was a major step toward greater consistency for many processors. Processes could be better controlled, resulting in improved coffee quality, which ultimately helped shape a mass taste.

With the rise of specialty coffee, the search for ever-new flavors, the research into the microorganisms in cherries, and the holistic understanding of fermentation as a tool for creating new flavors, the motivation and willingness to experiment of producers increased.

Since the 2000s, we have seen a sharp increase in post-harvest processes that range between the poles of pulped and non-pulped coffees.

New markets with new taste preferences have stimulated creativity in post-harvest processes, as have pragmatic considerations:

How can more water be saved in the processes?

How can a lot of coffee be processed in a small space?

And how do you create complex flavors using simple means?

We regularly receive coffees processed using new technologies, sequences, or bacteria. The field is open for experimentation—and if they taste good, these coffees will find a market. Nevertheless, these coffees also repeatedly irritate. I commented on this here a few years ago.

Fact sheet on the post-harvest processes

Over the years, there have been repeated efforts to break down the now steadily growing number of post-harvest processes into a graphic.

We're currently working on creating our own graphic, which we'll publish here . However, we'd like to share two graphics with you. One is from Tim Willems from 2019, who runs our farm in Nicaragua. The other is from Chris Kornman of Royal Coffee.

Both graphics are very precise. While Tim focuses on the sequence, Chris identifies the individual work steps that take place or do not take place for a particular post-harvest process.

Chris Kornman, Royal Coffee, 2020

Naming, taste preferences and possibilities

So far, the focus of our article has been on the mechanical processing steps, i.e., whether the coffee pulp is removed or not. An explanation in terms of processing steps will always be more precise than simply mentioning the fermentation method—or who knows what koji fermentation is? This post-harvest process might sound familiar to insiders. The name implies that koji mushrooms were used, but not how, when, at what temperature, for how long, or with what intensity. Even with koji fermentation, there are any number of combinations of processes.

The more we discuss the steps involved, and less the fancy names, the better we will gain an understanding of what exactly is meant by each coffee fermentation.

The choice of method for processing coffee after picking depends on various factors. And just as there is no best coffee, there is also no best processing method for coffee. The post-harvest processes always depend on

- volume of cherries to be processed

- Space conditions

- Access to know-how

- Access to tools

- Access to capital

- Target market - mass market or niche market

- etc.

On many farms these days, I see rain barrels, which were used for so-called anaerobic fermentation since the early 2010s, especially in Costa Rica , before this approach spread worldwide. These barrels are inexpensive and stable.

The more capital-intensive option is to use steel tanks , as is done in winemaking. The basic effects are the same, but steel tanks can be used at even higher pressure , similar to the carbonic maceration used in Beaujolais wine.

This process first became established among a small group of coffee producers and is still found in many places today. Conducting this process in a cooler environment prolongs the fermentation and, in turn, creates a new flavor profile. Specially air-conditioned rooms are created for this purpose, where the coffee is then fermented.

It seems as if every new idea for a modified fermentation protocol is embraced with great curiosity, applied, then refined, and further developed. However, this is done by a very small circle of coffee producers who bring the know-how, technical infrastructure, and a potential network of buyers.

This presents both opportunities and risks, but above all, it accelerates the growth of knowledge on the production side. The sensory diversity of these coffees can hardly be compared to a "traditionally" washed coffee.

Part 2: What do coffees made using different processing methods taste like?

Different processing methods can add flavors to a coffee that it didn't have before. Depending on the post-harvest process chosen, other attributes such as aromas, flavor notes, acidity, and texture can be influenced.

graphic

In our experience, the texture is the least affected by the fermentation method. A new aroma, however, emerges relatively quickly from the process.

The prerequisite for a soft and round texture is a high and uniform degree of ripeness.

If this isn't present, fermentation won't produce any "softness"—unless, and I first drank such coffees a few years ago from La Palma y el Tucán , lactobacilli are added, which can often have a positive effect on texture. Likewise, a reposa , which we do as standard in Nicaragua, can slightly enhance the perceived texture—but only if the cherries are already well-ripened and uniform. A good base material is needed to achieve a good or even better fermentation result.

Excursion on coffee fermentation: from risk to opportunity

What does coffee taste like that has been pulped in a demucilaginator (eco-pulper)?

Coffees that are pulped and degummed in a water-saving demucilaginator are the closest thing to what is known as washed coffees. Before demucilaginators, the coffee was mechanically freed of mucilage using fermentation before being washed.

Today, it's becoming standard practice for medium-sized and larger beneficios to use demucilaginators. This process eliminates fermentation because the seeds are pressed out of the cherry and the mucilage removed in just a few minutes.

Ecopulper / Demucilaginator at Finca La Bastilla in Nicaragua, 2017

Sensory remarks

- This efficient type of washed coffee often shows the pure character of the green coffee.

- The degree of ripeness and uniformity become clear - a high degree of ripeness promotes a soft texture, a high uniformity makes a balanced cup

- Since no fermentation takes place, no new flavors are added to the coffee

- The acidity is often very present, complex aromas play a secondary role

- These coffees show what the basis in a region can offer

Mucilage, Miel, Slime, Finca La Bastilla, Nicaragua, 2017

What is the effect of a reposa, a pause, before pulping?

When picked coffee cherries are not picked immediately but first rest for several hours in a controlled environment, this is called a reposa - a rest - in many parts of Central America.

I first encountered this years ago in Nicaragua, when I saw a full coffee cherry hopper late one evening. I asked my companion if the cherries shouldn't be pulped immediately. "No," he replied at the time – the reposa in a cooler environment (due to the nighttime temperatures) slows down the fermentation process, and "not much can happen."

The next morning, the coffee was pulped, fermented underwater, and washed. Today, this process is our standard procedure at Finca Santa Rita in Nicaragua . We wanted to understand exactly what happens during this process and conducted a research project with ZHaW. One sample was processed using the reposa method, while the control sample was processed without the reposa method.

Barbara Beck (photo above) investigated and documented the development of yeasts, bacteria and acids in this paper.

Sensory remarks

We rated coffees with a reposa approximately one point higher, for example, 83 instead of 82. Reposa coffees often exhibit a bit more sweetness, a bit more texture, but above all, better integrated acidity. Occasionally, we encounter reposa coffees that exhibit a slight fruitiness.

What does coffee taste like that has been pulped on a despulpadora?

Especially on smaller farms or in smaller, centralized beneficios, coffee is separated from the pulp using despulpadoras. Since most of the mucilage remains attached to the seed, the producer is faced with the choice of whether to dry the coffee with the mucilage attached to the seed (honey) or to remove the mucilage through fermentation, a biological process. This fermentation can be done in the open air, in a closed container, or underwater. The time required for hydrolysis, the breaking down of the pectin that holds the mucilage together, varies depending on the method chosen and potentially affects the flavor.

Despulpadora on Mil Variedades, our farm in Nicaragua

Sensory remarks

Pulped coffees often have the taste of a washed-demucilaginated coffee, which can reveal even more facets.

- often the aromas are more intense and go beyond the basic coffee taste

- the acidity often gains complexity

- Pulped coffees in parchment, which are fermented under water, often gain a bright, clear and fresh acidity

- Pulped coffees in parchment, which are fermented without water, often gain fruitier notes.

- Depending on whether the coffee is fermented in an even pile or an uneven pile, the coffees show more equal/unequal

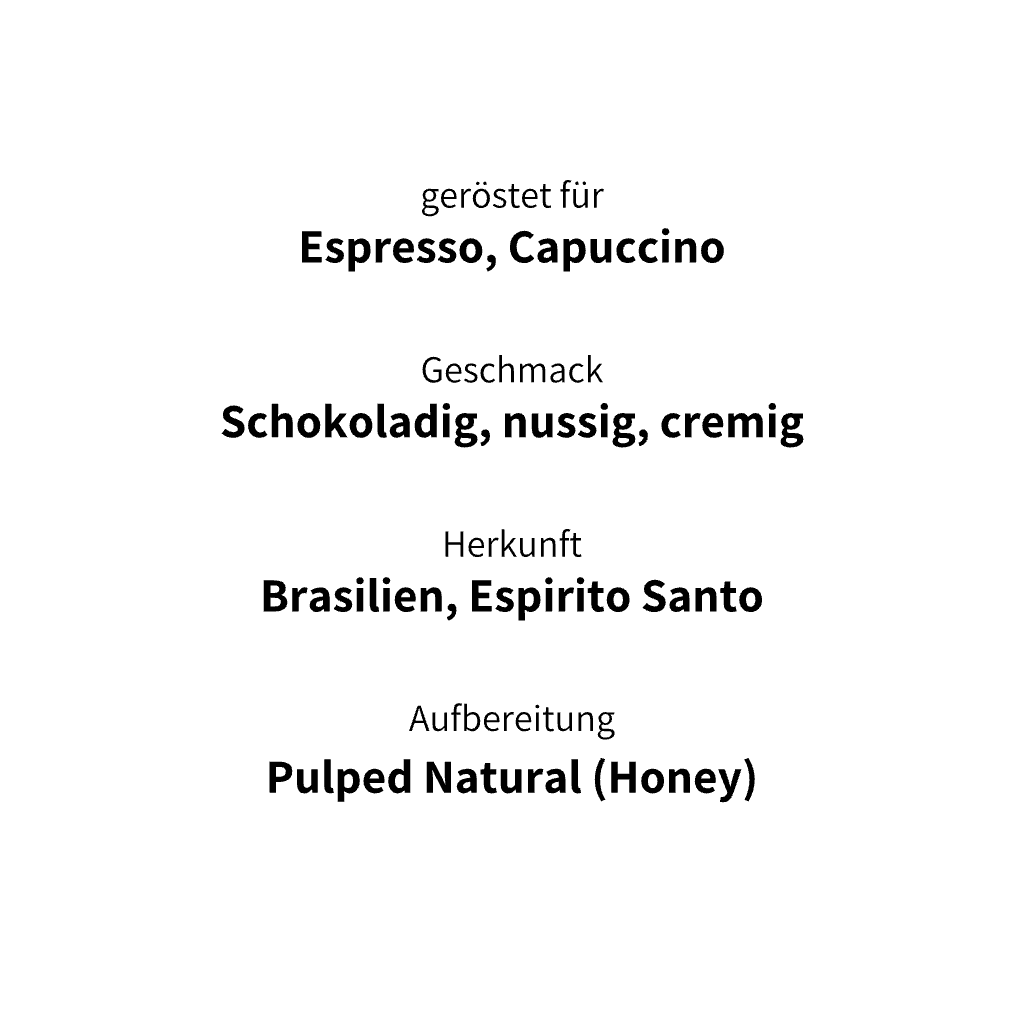

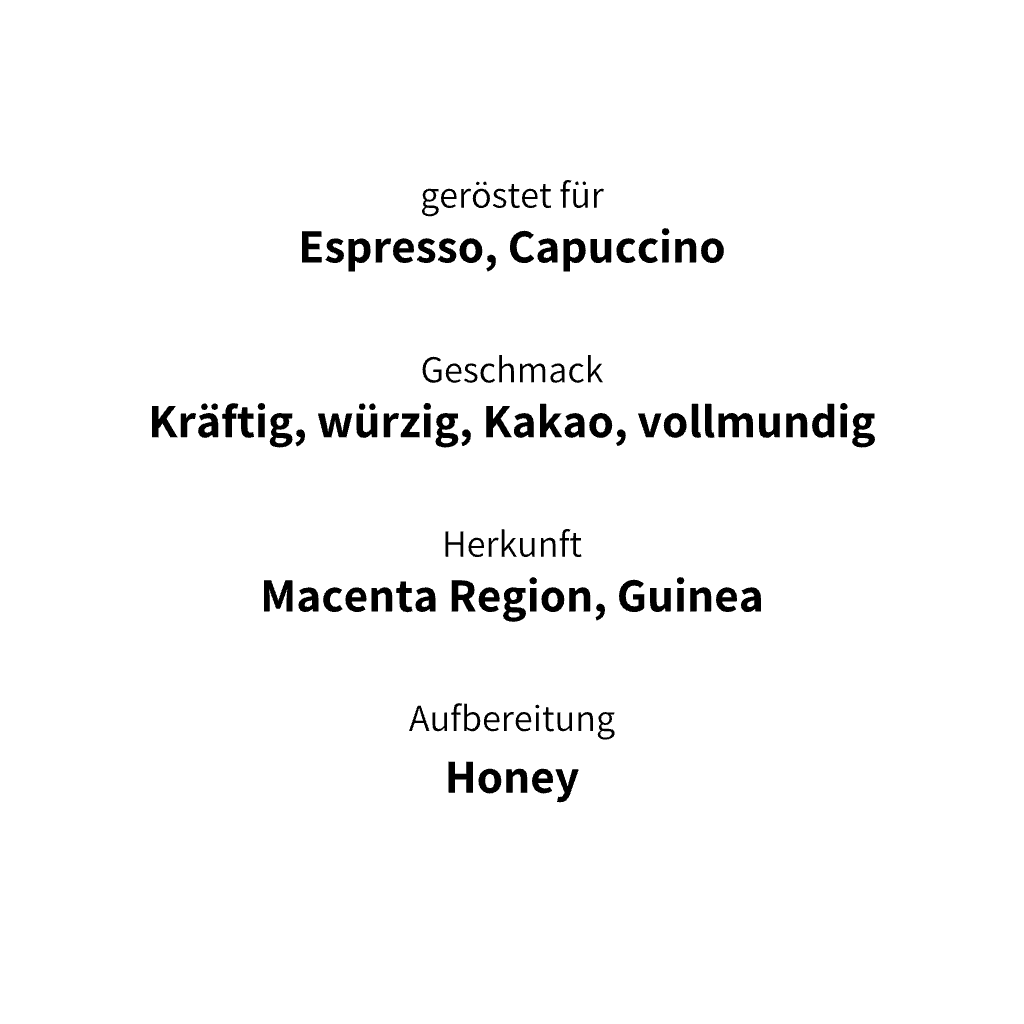

What do honey processed coffees taste like?

Coffees depulped on a despulpadora are fermented, as described above, to release the mucilage. The mucilage, or mucilage , is often called miel in Spanish, meaning honey. When translated back into English, miel becomes honey , and so we speak of the honey process when we mean depulped coffee that is dried with the mucilage layer.

The proportion of the mucilage layer and the length of drying, as well as the thickness of the accumulated layers and the prevailing temperature, play a role. Less honey on the seed promotes faster drying of the seed to approximately 12% residual moisture, while more honey requires longer drying.

A honey-processed dries in Ocotal, Nicaragua

In Costa Rica in particular, various amounts of honey are used. A lower percentage of honey in the parchment, such as 25%, allows for faster drying. This type is often called white or yellow honey because the small amount of honey in the parchment takes on a yellowish color. With 50% or more honey, the coffee dries more slowly in the parchment, and the honey becomes reddish, or even dark brown in the case of so-called black honey . There are no limits to the drying time and the percentage of honey in the parchment.

A Black Honey, Ocotal, Nicaragua

Sensory remarks

- White honeys are often reminiscent of washed and/or water-fermented, pulped coffees. They exhibit a balanced coffee, often with pronounced acidity.

- yellow honeys often bring a little more texture and slightly fruity nuances to the cup

- Red honeys exhibit significantly fruitier notes, derived from fermentation of the seeds. The acidity often fades into the background with this variety.

- Black honey coffees are often accompanied by dark fruity, chocolatey, or even luscious fruity notes

-

In general, more intensive honey processes can add a new layer of complexity to the coffee, often a pronounced texture

However, we also encounter many honeys where the clarity of the aromas and acids is masked. This is often due to the fact that the fermentation on the parchment paper cannot be very well controlled – unlike, for example, with intact cherries.

What do naturals taste like?

"Naturals," or "cherry-dried coffee seeds," used to be the opposite of "traditional washed coffee." Today, it's still true that the coffee seeds dry inside the cherry before the dried pulp is rubbed off. However, new types of fermentation and drying protocols have become established for naturals, especially in the last decade.

"In the past," it was believed that naturals had more sweetness and less acidity. Today, that's essentially the case.

We had naturals that were as lean as washed coffees. Then we had naturals that were lusciously fruity, and then we had naturals that had much more (acetic) acidity than their washed counterparts.

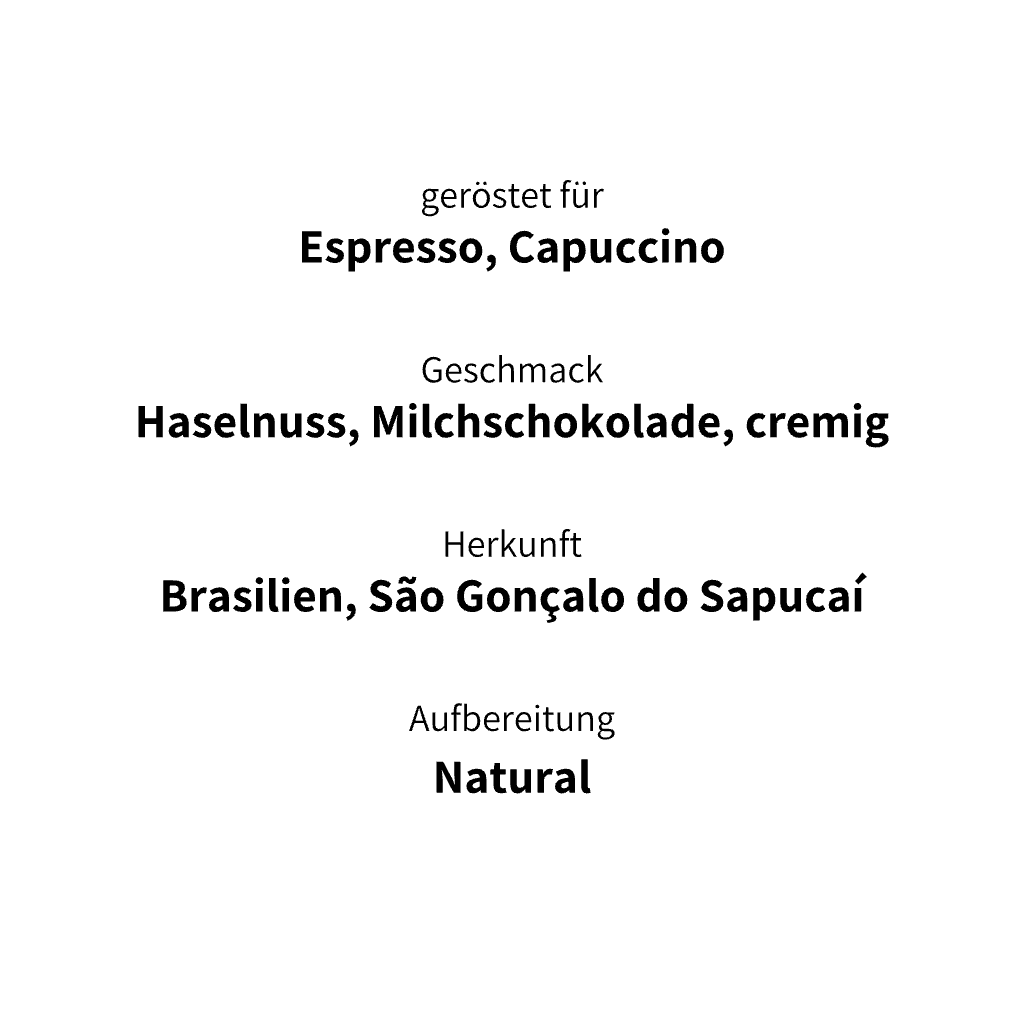

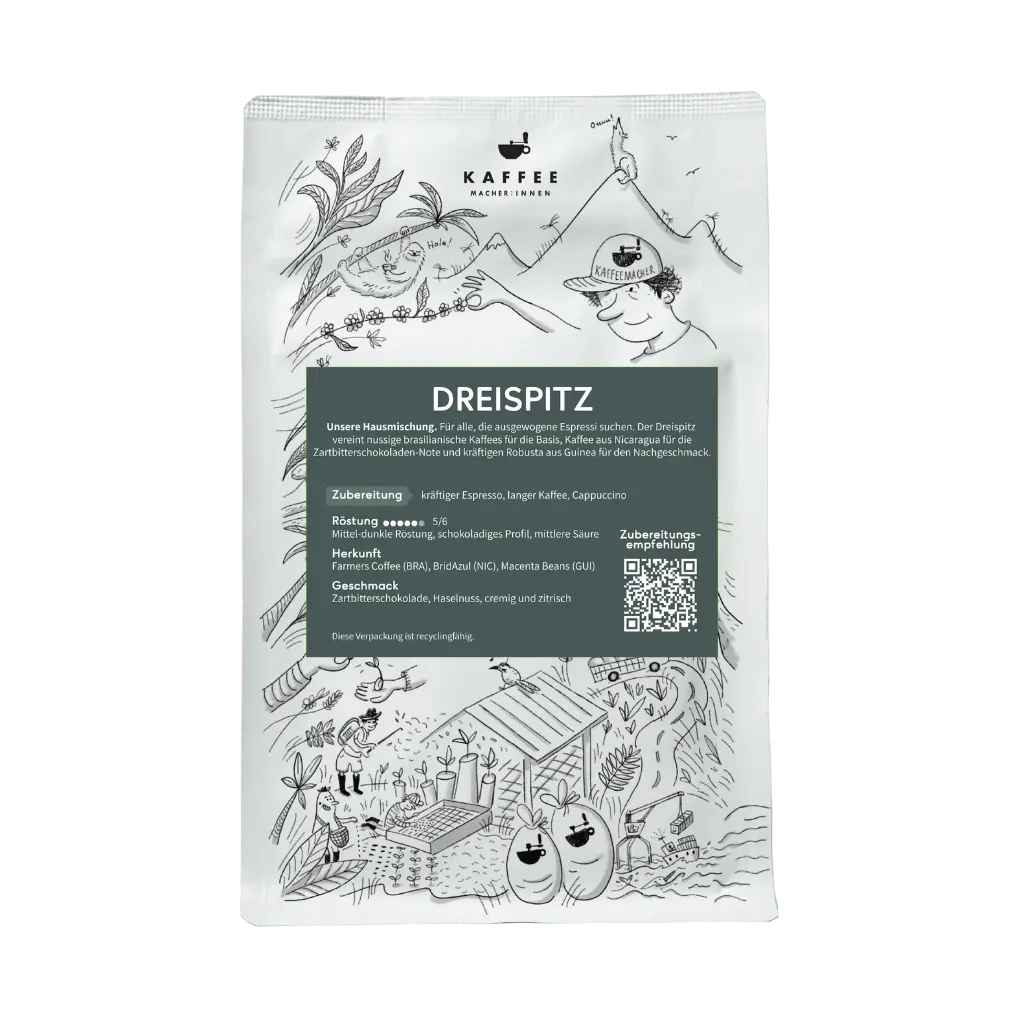

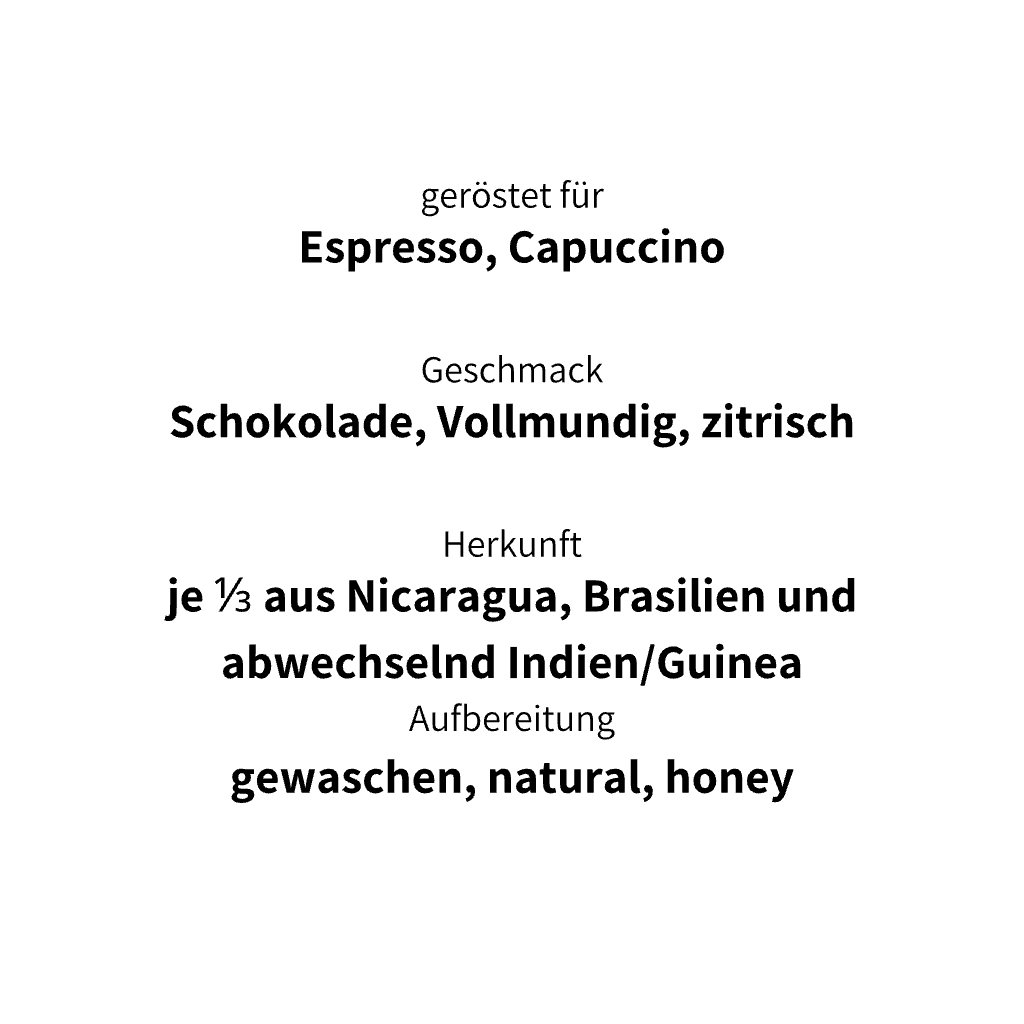

Many nutty, chocolatey coffees from Brazil are naturals, but not fruity (the bubble on the far left in the diagram). The white arrows do not mean that all dry-fermented coffees develop this way. Certain coffees are naturally fruity and can be made even fruitier through targeted fermentation. Other coffees, such as those from Brazil, are more nutty and chocolatey. These coffees may not be able to be given a tropical note if the raw coffee doesn't naturally allow it.

The degree and duration of fermentation define the flavors that can be evoked in the cherry by drying.

Over the past few years, we've conducted numerous fermentation experiments on our farm in Nicaragua. Many experiments failed or were complex, and failed to show significant sensory benefits.

There are now no limits to creativity in how coffee can be fermented. This offers many opportunities, but also carries risks .

What do highly fermented coffees taste like?

Highly fermented coffees add notes that wouldn't otherwise be present. We often use terminology that we wouldn't normally use for more traditionally processed coffees. It's important to embrace something new. Often, the vocabulary we've learned isn't sufficient to do these coffees justice. It's a bit like tasting natural wine ; we rely on a different vocabulary.

We have collected aromas that we repeatedly discover in strongly fermented coffees in the graphic.

What does a cold room do?

A cold room is a room cooled by air conditioning to a maximum of 16 degrees Celsius. Coffee is usually first placed in barrels and then brought to the cold room, where it begins or continues the fermentation process at a slower rate.

Cold room in Nicaragua with nitrogen cylinders to expel the oxygen in the barrels.

The cooler temperatures slow fermentation, so cold room fermentations can sometimes take 40 days or longer. This can result in incredibly rich, intense flavors. Our experience is that coffees from this fermentation often take longer to become truly stable.

In 2018, we had our first sample from Nicaragua, which—to say the least—displeased us. We kept 1 kg of the coffee and roasted it a year later. The coffee was suddenly balanced, no longer sharp, and very sweet.

What do coffees with added microbacteria taste like?

By adding microbacteria during the fermentation process, which takes place in a controlled environment (e.g., tanks), new reactions between yeasts, bacteria, and sugars can be triggered. This inoculation of the ferment, the substance to be fermented, only works if the microbacteria are still intact. For this to happen, they must be refrigerated. This process therefore requires not only great precision but also high hygiene standards and a well-equipped laboratory. These are criteria that very few coffee farms can meet.

One farm that creatively uses bacteria and yeast is Diego Bermudez's Finca el Paraíso in Colombia . These coffees often have rich, perfumed and fruity notes with strong intensity and a range of aromas not found in unfermented coffees.

What do coffees processed with yeast taste like?

Since the mid-2010s, coffees have been offered, initially without comment, and later with much comment, to which isolated yeast strands were added during fermentation. I wrote about the process and its derivation here .

Lucia Solis and Oleneska Cespedes are two engineers who make the topic accessible and concise. I was involved with Lucia Solis in a project in Honduras where we scaled up laboratory experiments with yeast fermentations to several tons.

In terms of flavor, yeast fermentation can be controlled with different yeast strains – similar to wine. Lallemand was the first to launch a special yeast strain for coffee cherry fermentation almost ten years ago. We also worked with various strains in Nicaragua, such as Intenso and Cima.

Intenso, as the name suggests, makes the coffee a bit more intense, in this case, fruitier. Cima slightly enhances the texture and length of the coffee. Yeast can't work miracles, but it can enhance what's already there.

Coffee yeast is something like an amplifier. Good things might get better, bad things might get worse.

Here, too, it depends on the quality of the raw material—in this case, the coffee cherries. Ripe cherries naturally contain a high concentration of sugar, yeast, and bacteria, so the initial conditions are good, and adding yeast can enhance or accelerate the metabolism.

Precision is required here: the water temperature for mixing the yeast, the quantity and the residence time in a tank have a massive influence on success or failure.

Night and fog action with Lucia Solis and coffee yeast, 2018

What do coffees fermented with koji mushrooms taste like?

Christopher Feran has worked for several years to establish a process using koji mushrooms, which made a big splash in the specialty food world in 2021. Koji is widely available in Asia and is used to make saka, miso, and other umami-rich products.

The great advantage of koji is that the fungi's own enzymes convert starches into easily available sugars , which then form new compounds with existing bacteria and yeasts during fermentation.

Christopher's blog post about this reads like a mixture of history, science fiction, and a recipe that makes you want to try such coffees.

The coffees we've tasted so far are as fruity and sweet as the best yeast-fermented coffees. Coffee Circle recently added a koji-fermented coffee to its range.

But here, too, any inoculated fungi or yeast strain can only perform as well as the raw material allows. The cherries must be of high quality for the process to produce desirable flavors.

Koji grows on coffee cherries. Source: Christopher Feran's Blog