Environmental impact analysis using the Cool Farm Tool as an example of Finca Santa Rita in Nicaragua.

Download study: Environmental impact of coffee cultivation Coffee makers

note

In this article/study, we calculate the carbon footprint of coffee using our Santa Rita coffee farm as an example, from cultivation to roasting. Santa Rita is located in the Dipilto region of northern Nicaragua and is a small farm of 4.16 hectares. The figures are based on the 2021/22 harvest and, given the relatively small harvest, are only a snapshot. At the time of data collection, large parts of the farm were undergoing renewal, so the harvest was low and the carbon footprint per kilogram was high. Above all, however, the study also presents a grid for calculating other coffee farms and their footprints along the coffee chain.

The study summarizes key aspects of our work in the research and work area of coffee makers' sustainability. This area is led by environmental engineer Tobias Milz.

Abstract

The CO₂ footprint for the 2021/2022 harvest was calculated using the Cool Farm Tool. It is a 4.16-hectare farm in Dipilto, Nicaragua, operated by the coffee makers in partnership with Bridazul. The calculation is based on a yield of 268.26 kilograms of exportable green coffee. The coffee farm was acquired by Kaffeemacher GmbH in 2017 and has been under renovation since then. During the period under review, less than half of the plants were in production (3,665 in production; 5,363 not in production). Fertilizers and pesticides were applied across the entire farm, not just on the high-yielding areas. Therefore, we expect a reduced footprint per kilogram in the coming years, partly through improvements in practices and partly through increased yields due to more trees in production.

The practice at Santa Rita is that no further processing steps are performed on the farm other than the harvest and initial cleaning of the coffee cherries. The harvested cherries are transported to the partner farm "El Arbol," located 7.4 kilometers away, for further processing. The next steps then take place at Bridazul's dry mill in Dipilto, another 23.3 kilometers away. The green coffee is shipped along with other coffees from the Dipilto region and transported to our roastery in Basel, where it is roasted and packaged.

The export-ready green coffee has a CO₂ footprint of 1.57 kilograms of CO₂ equivalent per kilogram, which corresponds to 101.15 kilograms of CO₂ equivalent per hectare and a total of 430.79 kilograms of CO₂ equivalent for the entire harvest.

We have deliberately chosen not to include the farm's existing trees and unused land as carbon sinks in our calculations. We cannot guarantee that the trees will remain standing for the next 50 to 100 years should wildfires occur or the farm be sold. If we were to include these, approximately 1,000 kg of CO₂ could be credited to the farm.

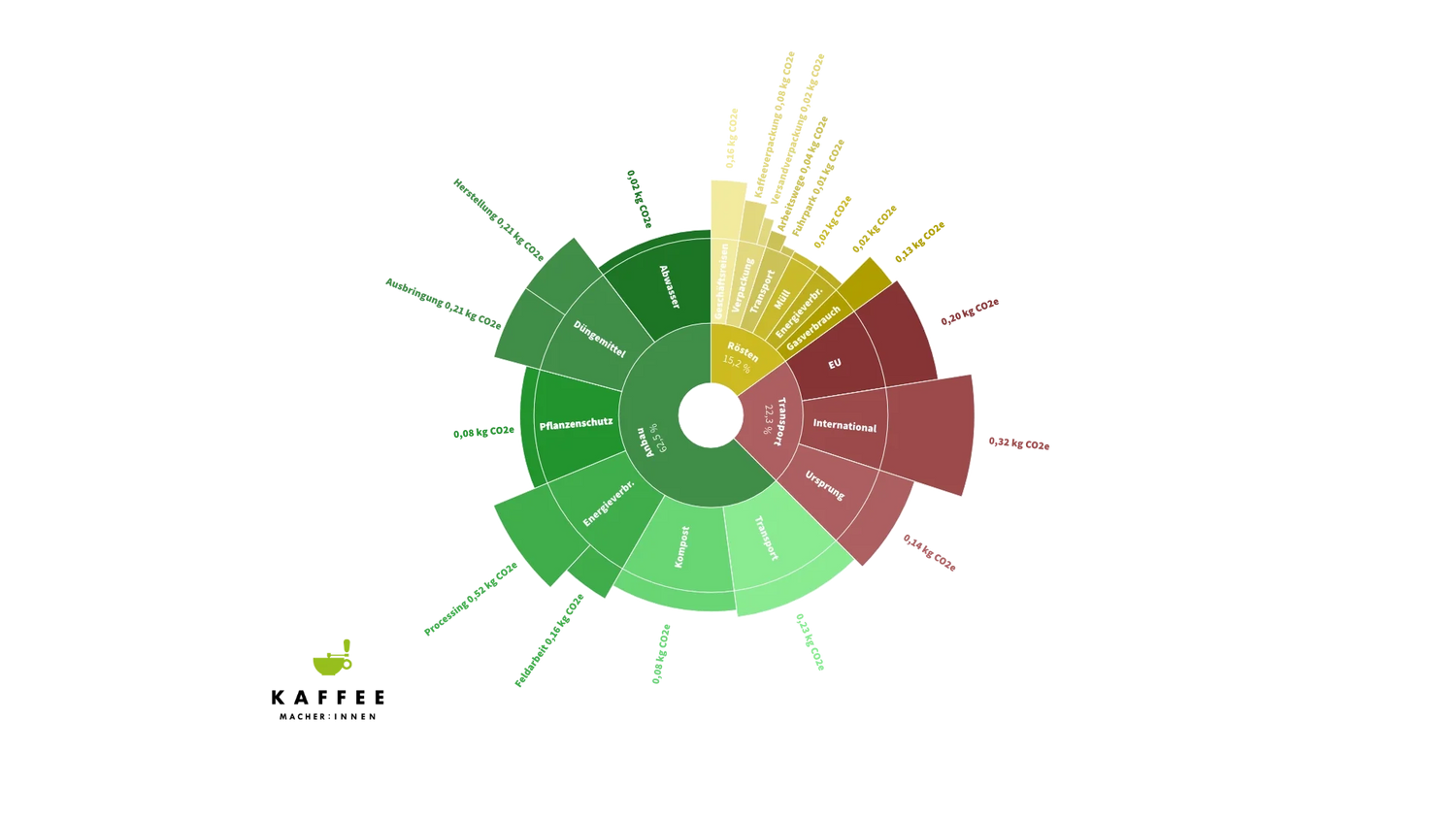

Distribution of emissions from Santa Rita roasted coffee

Overall, our calculation of transport and the footprint of the Kaffeemacher roastery in Basel results in a CO₂ equivalent of 2.96 kilograms of CO₂ equivalent per kilogram of roasted coffee in 2022, assuming a roasting loss of 15%. The distribution of this footprint is as follows: The majority, just under 1.85 kilograms of CO₂ equivalent per kilogram, is attributable to roasted coffee, which corresponds to approximately 62.5%. The transport share is 22.5%, which corresponds to 0.66 kilograms of CO₂ equivalent per kilogram of roasted coffee. The roastery generates an additional 0.45 kilograms of CO₂ equivalent per kilogram, which amounts to approximately 15%. The proportion of coffee from our own farm that is processed in the roastery is approximately 2%.

Introduction

The study is an environmental impact assessment of the coffee makers' Santa Rita farm, created using the Cool Farm tool.

farm

The farm is Santa Rita, with its associated Mil Varidades area, which has been owned by Kaffeemacher GmbH since 2017. The farm is located in northern Nicaragua, in the Nueva Segovia department, in the municipality of Dipilto. The farm covers 4.16 hectares and, at the time of data collection, has 9,028 coffee plants, of which 3,665 are in production. The farm has been undergoing renovation since being acquired by Kaffeemacher GmbH. Many plants have been removed, and new varieties have been planted. Typically, the plants bear their first cherries after three years. This explains why only a portion of the plants bear fruit.

The cultivation method is agroforestry with manual harvesting. Previously, crop protection was necessary to protect against Broca or Roya disease, and synthetic fertilizers and pesticides were used to promote plant growth. The goal is to gradually eliminate these. Instead, they will be replaced with biologicals and home-produced compost. In the next step, Bridazul and the coffee producers are working on a centralized and efficient production of high-quality compost from coffee production byproducts.

The farm is located 7.4 km from El Arbol, another farm operated by Bridazul. Bridazul partners with the coffee producers who operate the farm on-site. With the exception of an initial cherry selection, all essential post-harvest processes take place at El Arbol, not at Finca Santa Rita.

For further fermentation and cherry drying, the coffee is transported to Bridazul's dry mill in Ocotal, located 23.3 km away. The offices and laboratory are also located here. Before being exported, the coffee is hulled at Edman Café in the same town and packed in 30 kg jute sacks with liners.

Limits of the analysis

Typically, environmental impact assessments only consider the work on the farm. Since the farm wouldn't function without partners, off-farm work must also be considered. Therefore, various factors, such as energy consumption in the office and during processing, must be allocated proportionally to the farm's coffees.

The Cool Farm tool doesn't take waste or packaging materials into account. This means it doesn't include jute bags, liners, or other packaging used for either the coffee or its production.

The different resource situation in different countries is also not taken into account. Therefore, the calculation of energy consumption is based solely on a global average in terms of electricity consumption.

Uncertainties in the data

A major criticism of Environmental Impact Analysis (EIAs) is that uncertainties often receive little or no attention in communication.<1> However, every environmental analysis must deal with uncertainties and assumptions. Therefore, it is very important to identify them. Below, you will find the uncertainties assessed by category and contextualized.

We assessed the uncertainties according to the German school grading system, with a scale from 1 (very low uncertainty) to 6 (no certainty).

| Area | Evaluation | comment |

| fertilizer |

2 |

We know the exact amounts and types of fertilizers used The uncertainties lie in the composition information we found online and in the calculation. In our case, we included all fertilizers, including applications to plants that have not yet produced any yield. |

| Plant protection |

3 |

We know the exact quantities and types of pesticides used The uncertainties lie in the composition information we found online and in the calculation. In our case, we included all fertilizers, including applications to plants that have not yet produced any yield. |

| harvest |

1 | We know the exact amount of green coffee and roasted coffee. |

| Management of leftovers | 2 |

Relatively accurate estimate of Casulla's mass. Casulla is what's left over from the first grinding. It contains more pulp than cascara. Cascara is the skin that remains after pulping. |

| transport |

1 | Distances and workload, as well as vehicles are known |

| Energy demand |

2 | The calculations clearly show how consumption is broken down. Uncertainty regarding distribution and electricity mix |

| Soil properties |

4 | The soil studies are no longer up to date (2019) |

| Processing |

2 | A good base. However, the levy is an average for all Santa Rita coffees. |

| Wastewater |

3 | Expert estimate |

Collection of data

Most of the data was collected on-site in April 2022. Using a questionnaire specifically developed for coffee farms and comprising over 200 questions, all ecological, economic, and social factors were collected. Further details for the calculation were subsequently provided by Bridazul. Bridazul invoices the coffee makers for all work carried out on Santa Rita, including the materials used. This allows for very precise tracking of what, how much, and when was used.

Furthermore, the coffee makers are the only buyers of the coffee from the farm, so it's possible to say exactly which processing was applied to each coffee. However, the calculation requires an average, which affects water and energy consumption.

Result

The calculation shows that the total footprint of the 2021/22 harvest is 420.78 kg CO₂ equivalents. This corresponds to 101.15 kg CO₂e per hectare and 1.57 kg CO₂e per kilogram of green coffee.

| CO2 | N20 | CH4 | CO2e | CO2e per ha | CO2e per kg | |

|

Wastewater |

0 | 0 | 0.22 | 6.03 | 1.45 | 0.02 |

|

Management of leftovers |

0 | 0.04 | 0.37 | 20.71 | 4.98 | 0.08 |

| Fertilizer production |

57.03 | 0 | 0 | 57.03 | 13.71 | 0.21 |

| Soil / Fertilizer |

0 | 0.21 | 0 | 57.12 | 13.73 | 0.21 |

|

Plant protection |

36.30 | 0 | 0 | 36.30 | 8.73 | 0.14 |

|

Energy consumed (processing) |

139.50 | 0 | 0 | 139.50 | 33.53 | 0.52 |

|

Energy consumption (field) |

41.80 | 0 | 0 | 41.80 | 10.05 | 0.16 |

|

Transport outside the company |

62.29 | 0 | 0 | 62.29 | 14.97 | 0.23 |

|

SUM |

420.78 | 101.15 | 1.57 |

Energy use (electricity)

At 33.2%, energy emissions from processing are the largest factor. This is due to the fact that the coffees are highly processed.

The coffees undergo a controlled fermentation process at Bridazul, which also provides a cold storage facility to ensure a controlled environment. This results in high energy consumption, even though the process only runs for one month a year. Assuming electricity costs of $0.05 per pound of green coffee, this equates to 126.56 kWh of energy consumed for our coffees.

fertilizer

On many farms where plants are exposed to full sun, fertilizers account for a large portion of emissions (> 80%). This becomes clear when considering the assumptions used in studies such as Ecoinvent. Ecoinvent is a widely used environmental database. However, Ecoinvent does not maintain a dataset for coffee from Nicaragua, but does maintain one for Honduras. Due to the farm's proximity, this dataset can be used. Here, an application of NPK fertilizers of 343-223-221 kg/ha is assumed, resulting in emissions of 10.11 kg CO2e/kg of green coffee.

Santa Rita applies 6.56-5.80-26.67 NPK fertilizers. This includes organic fertilizers and fertilizers for plants that are still growing and not producing any crops.

The high fertilizer application in the Honduras dataset achieves a yield of 1340 kg/ha. The yield at Santa Rita, in comparison, is 101.15 kg/ha. Thus, the yield is 13.25 times higher. However, the fertilizer application factor for nitrogen (N) is increased by a factor of 52.29, for phosphorus by a factor of 38.45, and only for potassium is the factor smaller than the yield factor (8.29). However, yield is expected to increase in the coming years as more plants enter the production phase. (Coffee plants typically begin to bear cherries after three to four years.)

transport

Transportation is a major factor at 14.8%. This is primarily due to the need to transport the workers and all equipment to the farm, as no one lives on the farm except for two employees. However, this does not include transporting the coffee to the port. We charge for this separately, along with shipping and transportation within the EU.

Roads in remote regions of Nicaragua cannot be compared with roads in Switzerland, and the additional costs caused by unevenness or lack of asphalt must be taken into account.

discussion

Comparison of emission data from green coffee

Existing environmental data for coffee vary widely or are unavailable. Data in environmental databases such as Ecoinvent aim to cover a high degree of generality. Therefore, the focus is on coffee-producing countries such as Brazil, Vietnam, Colombia, Indonesia, and Honduras, which account for 85% of global supply. The remaining 15% is distributed among another 55 coffee-producing countries and therefore receives less attention in large-scale studies.<2>

For this reason, Ecoinvent does not maintain any data for Nicaragua. Since Honduras is Nicaragua's neighbor and uses similar agricultural practices, and coffee cultivation in Honduras is similar to that in Nicaragua, a comparison is appropriate. The Honduras dataset shows 10.11 kg CO2e / kg of green coffee<3>. The dataset from Carbon Cloud, a freely accessible database focused on food, shows 4.0 kg CO2e/kg of green coffee<4> for coffee from Nicaragua. A study by Caravela Coffee, which also considers carbon storage through the agroforestry system, arrives at approximately -12.7 kg CO2e/kg of green coffee<5>. The farm in question is therefore in the middle range of these values. If the change in use were taken into account on Santa Rita, approximately 4 kg CO2e/kg of green coffee would have been stored on Santa Rita. This only takes into account the area no longer managed as forest. In addition, there would be new trees and shrubs such as bananas and inga.

Comparison of emission data of roasted coffees

The analysis of roasted coffee includes cultivation, transport and roasting (roasting in our calculations also includes packaging). In order to find reliable data for roasted coffee, a very detailed examination of the studies and the database on which they are based is required. A frequently cited study <6> “Life cycle assessment synthesis of the carbon footprint of Arabica coffee: Case study of Brazil and Vietnam conventional and sustainable coffee production and export to the United Kingdom” shows a footprint for consumption in the UK of 14.61 kg CO2e / kg roasted coffee for conventional coffee from Brazil. However, the coffee in this study was flown. Which is extremely rare.

Ecoinvent doesn't offer any data. Carbon Cloud provides various data sets, but they are all primarily based on coffee from Brazil. Thus, the data are very similar.

Roasted coffee from Santa Rita

To calculate the footprint of the farm's coffees, we used two additional tools that we developed ourselves as a company: a roaster footprint calculator based on Ecoinvent data and a transport calculator based on Mobitool data (as of 2023).

The Kaffeemacher roastery's footprint for 2022 has already been published. The roastery's emissions for 2022 amount to 22.122 t CO2e, which corresponds to 0.45 kg CO2e per kg of roasted coffee.

The coffee producers purchased 4,780 kg of coffee from Nicaragua in 2022. This includes Santa Rita coffee. Emissions from transport amount to 2,692.19 kg CO2e, of which approximately 150 kg CO2e is attributable to Santa Rita coffee, or 0.56 kg CO2e per kg of green coffee.

A 15% roasting loss must be taken into account for both farm emissions and transport emissions. This results in a CO₂ footprint of 2.96 kg CO2e per kg of roasted coffee.

| green coffee | Roasted coffee | distribution | |

| Cultivation | 1.57 | 1.85 | 62.50% |

| transport | 0.56 | 0.66 | 22.30% |

| Roastery | 0.45 | 15.20% | |

| In total | 2.51 | 2.96 | 100% |

What is missing?

The coffee chain continues, because after roasting, coffee is consumed by you at home and consumed by us in the restaurant industry. Some 250-gram bags are sent around the world by mail and then brewed as a filter or espresso? What impact does this have? What effect does a thermoblock or a 2.5-liter boiler have on electricity consumption and footprint.

We've explored these questions. You can find the first draft and the current status on our sustainability page.

If you're missing a link or interested in our work in this area, sign up for our newsletter to stay up to date on other topics in this area.

The 2022/23 harvest has now been harvested on Santa Rita, and the 2023/24 harvest is currently underway. We will soon be able to add additional years of data to the study.

If you have any questions or find any logical errors, please comment or write to us. Thanks in advance!

Sources

<1> https://www.tandfonline.com/doi/abs/10.3152/147154606781765345 , as of: December 20, 2023

<2> https://coffeebarometer.org/explore-coffee-barometer/ , as of: 12/20/23

<3> https://v38.ecoquery.ecoinvent.org/Details/PDF/90C86EF0-3AFE-4D85-8885-779EBE69FAD4/290C1F85-4CC4-4FA1-B0C8-2CB7F4276DCE , as of: 12/20/23

<4> https://apps.carboncloud.com/climatehub/product-reports/id/74726502789 , as of: 12/21/23

<5> https://caravela.coffee/project/producing-greener-coffee-at-farm-level/#whitepaper, as of: 12/20/23

<6> https://rgs-ibg.onlinelibrary.wiley.com/doi/full/10.1002/geo2.96 , as of: 12/22/23