Does coffee from small roasters taste better than that from large ones ? And are "industrial roasters" actually inferior roasters? And when does a roaster actually become a large roaster? We wanted to understand more about who actually roasts how, so we spoke with both small and large roasters. We've summarized the results here in an overview. In short: many things aren't as they seem.

During coffee roasting, raw coffee is heated to specific temperatures for a specific time. During this process, the coffee undergoes various physical and chemical processes. The formerly green beans become brown beans, which are then ground and extracted.

As simplified as the roasting process is described here, it is actually quite simple. Green turns brown. The processes that follow during coffee roasting are the same – whether 50g of coffee, 5kg, or 500kg are being roasted. However, they differ in their intensity, duration, and precision.

- So if roasting is theoretically so simple, why do the same coffees taste different from different roasters?

- And why are larger roasters often criticized for roasting large quantities quickly?

- And is that even true?

- And why, according to common belief, is coffee roasted in smaller batches supposed to be much better?

The “800° for two minutes” roast

Many of these statements seem like truths because they are repeated over and over again. And when we hear the same statements over and over again, they feel like truths (known in psychology as the truth effect ).

For example, the "800°C roast for two minutes." Also known as high-yield roasting, the very large roasters do. Yes, this was the way coffee was roasted, and we still find this roasting style today, but it's probably much less common than you think. Not every supermarket offers the worst coffee, and not every small roaster offers the best coffee.

We wanted to know more and spoke with roasters both small and large. Aldi, Melitta, UCC Switzerland, and Delica explained their roasting philosophies. Hochstrasser and Rast Kaffee explained their roasting practices, as did the nano-roasteries Birchbach Coffee and Röststube Lübeck. We also opened up our roasting notes and explained what we actually do, for example here .

Contrary to expectations, our responses were met with extremely receptive ears. Very few roasters failed to address our concerns. It seems that, especially among the larger roasters, there is a need to share their own perspectives. Many also saw it as an opportunity to correct mere assumptions and even offer sharp rebuttals – although this was subsequently toned down by the marketing departments. At the end of the day, some large roasters were considerably more cautious.

Prologue: Gentle drum roasting vs. industrial roasting

Far too often, we hear and read the same, imprecise statements about large roasters. They roast at 500°C to 800°C in two minutes, claiming the green coffee doesn't break down chlorogenic acid, and claiming the green coffee quality is poor. In contrast, the concept of small roasters is presented, which roast with smaller batches, significantly longer roasting times, and at lower temperatures. It's supposedly "gentle" and therefore better.

As coffee makers, we take great pleasure in small projects driven by passion, in craftsmanship, and in a genuine interest in getting to the bottom of things. However, we find little value in the above statements. The information content is thin, and the denigration of one roasting style serves to exalt another. In addition, the discussions about industrial and small-scale roasters are often very emotional.

It often seems as if, on one side, there are the small roasters, who mostly work with drum roasters, and then, on the other side of the spectrum, there are the so-called industrial roasters, who roast just anything. As if the coffee world only consists of small and large, white and black, good and bad, and with or without milk. But it's much more complex.

We often hear and read criticism of the large roasters – regarding coffee quality – from smaller roasters. Yet many roasters have no need to make disparaging comments about other roasting approaches.

Mirjam Baumgartner installs the very large roasting machines for Bühler, one of the leading manufacturers of industrial roasting equipment. Baumgartner doesn't hold back with her assessment:

The quality of the coffee doesn't depend on the size of the roastery, but on the quality of the raw material and the understanding of the craft. And this is a matter of the roastery's philosophy.

Mirjam Baumgartner

And she continues:

"Gentle, slow roast," "hand-roasted," or "roasted using traditional drum roasting methods" are about as specific as calling someone a "hipster." While you know roughly what that means, it's simply not clearly defined. Such statements are an attempt to distance yourself from big industry.

Mirjam Baumgartner

And Baumgartner is right. Differentiation through devaluation is easy, but it ignores the fact that different roasting approaches, coffee, and green coffee qualities enrich the market and are necessary.

This article attempts to paint a nuanced picture of roasteries of all kinds. At the same time, it is a plea and a request to roasters to communicate their own strengths in their applications and thus demonstrate self-confidence, rather than trying to distinguish themselves through derogatory differentiation.

A new categorization of the roasting landscape

In 2007, Probat created its own definition for industrial roasting in the standard work “Industrial Coffee Refinement”:

“'Industrial roasters' are defined as those with a roasting container capacity of 60 kilograms or more, which corresponds to the standard weight of a green coffee sack.”

Probat, 2007

Coffee Circle in Berlin roasts on a 60kg Probat roaster, so according to the Probat definition, which only considers volume, it would be an "industrial roaster." Does that help us? Not really. Because Coffee Circle defines itself quite differently and probably doesn't consider itself an "industrial roaster." Moreover, the term has become massively charged in recent years, especially with derogatory connotations.

A classification into small and large roasteries, or even into so-called artisanal and industrial operations, remains superficial. Here, we attempt to reclassify roasteries based on precise criteria and rename them in the process. We compare them by size and roasting machines.

Comparison 1: The size of a roastery – from nano to mega

Roasteries are limited in size by customer demand, the choice of roasting equipment, or by a conscious decision to maximize production. Depending on their size, roasters share similar processes and challenges. This makes dividing them into size groups sensible. Dividing them into five groups facilitates communication about roasters and, due to similar processes and challenges, also makes sense in terms of content.

This allows us to better differentiate between smaller roasters and the mid-range, and move away from the emotive term "industrial roaster." We propose nano-, micro-, meso-, macro-, and mega-roasteries.

Our proposal for a new categorization of roastery sizes (2020).

Our proposal for a new categorization of roastery sizes (2020).

Nano (1t-5t roasted coffee per year)

A nano-roastery roasts between one and five tons of coffee. The roasting infrastructure consists of a 500g–2.5kg roaster or a larger roasting unit used only on a few days.

The roastery project is run alongside a full-time job or is integrated into an existing business (café, roastery, retail store). Most processes, such as packaging, are carried out manually. The range of green coffee beans is rather small, as the market typically offers 60 or 69 kg bags, and these must first be roasted in many small batches.

From practice

When we started our coffee-making roastery, we were able to roast seven tons of coffee in the first year. The term "nano roastery" was a good fit. We're now in our fourth year of roasting and approaching 30 tons per year. The term "nano" hasn't been appropriate for a while now, as we know of dozens of smaller roasteries that have just started. Flavio Lissandrello of Birchbach Coffee calls his project "Nano Roastery" because he doesn't intend to grow much. Flavio roasts on a Bullet, a 1 kg roaster.

Examples: Birchbach Coffee , Röststube Lübeck

Micro (6t – 50t)

Over the years, work processes have become more professional, and the product range has become more consolidated. The green coffee purchasing strategy has been refined, and more customers have more differentiated needs. Depending on the production location and cost structure, a permanent full-time position is created and financed for approximately every 15 tons. The roastery is no longer a side project, but has become established—we refer to it as a micro-roastery. At this point, many roasters consider how long they want to continue roasting with their first machine and when an upgrade to a larger roaster is due. A stable customer portfolio helps with this decision, and roasters often upgrade immediately. From a 5kg roaster to a 15kg roaster, a 12kg roaster to a 35kg roaster, or from a 15kg roaster to a 45kg roaster.

Examples: Kaffeemacher, Adrianos , Miro , Vertical Coffee , Günter Coffee Roasters

In micro-roasteries, almost everything is packaged manually.

In micro-roasteries, almost everything is packaged manually.

Meso (51-200t)

Anyone who roasts this much coffee has already created several full-time jobs. With a larger machine, more coffee is roasted in less time, and production costs begin to decline. At this volume, less and less manual packaging is required. Conveyor systems, volumetric electronic pre-portioners, and software interfaces between ordering and production planning help optimize the workflow and place increasing emphasis on post-roasting . The roasting itself is often automated – a program originally created by the roastmasters is now often replicated by a computer. This allows for more freedom and even more control. The focus at meso roasteries is increasingly shifting towards packaging and shipping. Logistics is becoming more important and must be coordinated with ever greater precision.

Macro (201-2000t)

A macro roastery often roasts in multiple shifts and produces a good 1,500 tonnes per year from a 250 kg roaster. Such roasteries typically have additional, smaller roasters (25-100 kg), which can also accommodate private label offerings. The roasting machine itself takes up less space in a macro roastery. The surrounding peripheral equipment, such as blending silos, roaster loading, stoning, transport pipes, grinding systems, and packaging equipment, are now much more reminiscent of a well-thought-out work process. Capacity utilization becomes the key here – such large facilities can rarely be idle. Especially roasteries of this size often offer private label offerings, where coffee is roasted for third parties.

Example: Hochstrasser Coffee Roastery

Mega (2000t – 100,000t+)

The main difference compared to the very large roasters is that more and more processes are being mechanized. In a roastery that roasts 20,000 tons annually, a shift might involve just six production employees. In micro-roasteries, which are about 1,000 times smaller, a shift might also involve three to four people if everything is to be packed manually and delivered quickly. In mega-roasteries, coffee is barely visible anymore. After roasting, it travels through various channels, possibly grinders, until it is finally packaged by packing machines.

The larger a roastery becomes, the more efficient the equipment, the significantly reduced the working hours.

The larger a roastery becomes, the more efficient the equipment, the significantly reduced the working hours.

Comparison 2: Roasting machines

It's obvious that larger roasters can only roast so much with larger roasting machines. In contrast, small roasters often roast for several years with smaller machines. Purchasing a roasting machine isn't a walk in the park for any roaster. Even a 1 kg roaster represents an investment of up to 10,000 Swiss francs. A 400 kg roaster, including the necessary peripherals and installation, represents an investment in the millions.

Of course, there are technical and quality differences within the size range of roasting machines. At the end of the day, however, a roasting machine is like a car. Every car will get you from A to B, you just have to know exactly how. So, with the focus on potential roasting quality, there's no such thing as a better or worse roasting machine. The demands placed on the machine, the roasting style, the level of reliability, and the level of convenience make the biggest differences here.

Roasting machines at nano roasteries

In recent years, more and more micro-roasting machines have come onto the market, and we're also seeing a growing number of nano-roasteries that can offer their clients even the smallest batches. These micro-roasting machines typically roast beans with hot air, a lot of movement, and a shorter roasting time. It's simply not worth it to heat up a lot of material for a small batch and roast the beans using contact heat. Instead, convection is receiving a lot of attention. This roasting approach, with its focus on heat transfer through large amounts of hot air, dates back to Michael Sivetz's fluid-bed technology from 1975. Small batches can be roasted precisely and replicated.

Examples: Roest , Ikawa , Neotec , Aillio Bullet

Roasting machines at micro-roasteries

Micro-roasteries strive to represent authenticity and craftsmanship through their craft. For many, this includes a powerful roasting machine, where much of the roasting is done by hand. Some roasteries completely forgo any degree of automation because, for them, it doesn't correspond to the idea of craftsmanship they want to represent. At the same time, a roasting machine, in this case a drum roaster, simply makes a great impression on many people. A steel colossus weighing at least 500 kg, still somewhat shiny, is usually well-positioned in a roastery or café to demonstrate that the roasting is still done in-house.

Drum roasters are the first choice for many. An outer casing is heated by direct or indirect heat and keeps the system hot. Inside, a drum rotates, clockwise or counterclockwise depending on the manufacturer, within which the green coffee is agitated by precisely shaped fins and paddles. Heat transfer in these roasting machines is a combination of the air flowing through the roaster, the heat transfer through the hot material, and the heat transfer from bean to bean.

Drum roasters sound like history and, for many, the true way of roasting. But ensuring the coffee always tastes the same requires a precise understanding of how to operate the roaster, its peculiarities, and its behavior.

Roasting machines at Meso roasteries

These roasters have already purchased a second, or even a third, roasting machine. It generally makes sense to upgrade from a 15 kg machine to one at least three times larger, as this can often be quickly brought back to full capacity.

If we assume that a roastery roasts 3-4 batches per hour, 6 hours a day, 5 days a week, with a roaster operating at full capacity (15kg roaster = 15kg green coffee), then while it can roast approximately 60+ tons per year, roasting takes place every day, and the strain on the infrastructure and the team is high.

A 35kg roasting machine, for example, roasts 70 tons per year in half the time, making it significantly more efficient. Many roasters upgrade to a significantly larger machine at this point.

Larger roasting machines, however, also require a larger conveyor system, more efficient air filters, cyclones, and possibly an afterburner or a different air filter. We're no longer talking about just one roasting machine , but an entire roasting system , where the roasting machine itself takes up only a third of the space.

The "traditional" roaster brands like Probat , Joper , and Giesen have settled on these roastery sizes and offer complete systems for them. Diedrich offers an intermediate solution with a 25 kg roaster in its range, which is designed to cover this size transition.

Roasting machines at macro roasteries

Macro roasteries operate technically similarly to meso roasters, except everything is a bit bigger. A larger drum roaster, a more efficient transport system, a larger green coffee elevator, a larger packaging facility—the Goliath of artisanal roasteries.

Drum roasters with capacities ranging from 140 to almost 300 kg per batch operate on the same principle as their smaller counterparts, but they require significantly more energy. Anyone who wants to roast 300 kg of green coffee in 15 minutes in a drum roaster requires a lot of gas and a corresponding supply line or tanks.

Roasting machines at mega-roasteries

Theoretically, the drum roaster principle could be scaled up even further, but the system is becoming increasingly inefficient. And large roasters are geared toward efficiency—so the drum roaster process is out of place.

Batch sizes range up to 500 kg or even more. And here, roasting with hot air is significantly more efficient. These roasting systems blow and push the coffee in elliptical shapes over long distances. A hot air stream surrounds the beans and can heat them up in a short time. These tangential or tray roasters take up a lot of space and consume a lot of energy. However, they partially recycle the hot exhaust air, allowing the system to retain the heat.

The temperatures in these systems are also significantly higher than in a traditional drum roaster. Mirjam Baumgartner from Bühler again comments:

Air temperatures always depend on the air-to-bean ratio. However, the amount of heat transferred to the beans and the temperature development of the beans are important. The chemical reactions that create flavor take place within the beans, not in the ambient air. Accordingly, you can roast at 450°C in 3 minutes, provided you want to and have enough air available. Some of the world's most commercially successful coffee products use short-time roasts. Roasting air temperatures range anywhere between 450°C and 280°C.

Mirjam Baumgartner

The ultimate form of fast and efficient roasting is the so-called consecutive roast. Unlike batch roasters, in which coffee is processed in fixed batches, continuous roasting involves constantly adding coffee to one side and removing roasted coffee from the other. Probat writes:

“Due to the high proportion of convection, continuous roasters allow for relatively short roasting times with low burn penetration. (…)

I haven't been successful in my attempts to contact the very large roasters with continuous roasters. In addition to the rapid processing of large volumes, the continuous roaster has another advantage, as this quote from the Probat book demonstrates:

Since the drum in this system is not perforated, green coffees with a high proportion of broken beans can be processed without any problems.”

p. 37, Industrial Coffee Processing, 2007)

Broken grains, quick roasting, grinding – it's primarily about the most efficient processing, more or less consistent taste, and no longer about quality.

Roasted coffee quality. Who roasts how, and, most importantly, who roasts better? And why?

For me, the main difference between good and less good roasters is whether they operate consistently. Whether all batches taste as desired, or whether unforeseen mishaps occur. Again, understanding your own machine is key here.

The smaller the batch, the greater the potential for deviations, and vice versa.

Large roasters therefore have a clear advantage when it comes to the differences between individual roasts. Larger systems are slower because they move more mass – but those who can take advantage of this can roast incredibly consistently.

Small roasters are more susceptible to fluctuations—the smaller amount of material stores less energy than larger systems. Temperature fluctuations in the roastery can affect the small drum, as can slightly different air pressure. Of course, it's possible to work precisely and consistently with small roasters, but it requires intensive study of the technical peculiarities of the machines—and this is where I see a lot of potential in the small roasting scene.

If we just look at consistency, I've had significantly more consistent roasts from meso, macro, and mega roasters. The most inconsistent roasts I've had so far have always been from nano and micro roasters.

So what exactly is “industrially roasted coffee”?

It's clearly insufficient to divide the roasting world into micro and industrial. There are various scales in between, and some of these are significantly more industrial in their function (more efficient, larger, more technical, more automated), although they still have the appearance of an artisan roastery.

automation

It seems that the high level of automation at large roasteries is bringing the industry comparison to the fore. The level of automation that seemingly only requires roastmasters to monitor the roasting curves in front of a screen, but no longer actively intervene.

With more automation, some of the romance that first drew so many roasters to roasting in-house is lost. The manual, the artisanal approach, the risk that things can sometimes go wrong because we as humans have reacted incorrectly—the guarantee that everything will never work out as planned—has become, for many, the epitome of true craftsmanship.

Freshness

When it comes to freshness, small roasters that sell directly or through their own shops score significantly higher. The very large roasters sell their coffee through retailers, which in turn have their own intermediate warehouses. It takes several weeks for the coffee to travel from the roastery via the intermediate warehouse to reach the shelves.

Green coffee sacks at nano- to macro-roasteries. Big bags of 1,000 kg each predominate in mega-roasteries.

Green coffee sacks at nano- to macro-roasteries. Big bags of 1,000 kg each predominate in mega-roasteries.

There are differences between small and large. And those who roast more provide more people with coffee, make more friends, but also have more critics. More volume smacks of more consistency, and this, of more unity. Unity in the process and often also unity, even uniformity, in the taste.

Do coffees from small and large roasters taste different?

Ideally, coffees from small and medium-sized roasters taste more diverse than those from very large roasters. Nano and micro roasters, with their smaller drum roasters, can roast smaller batches. The smaller batch sizes also encourage the roasting of very small quantities, so-called nano-lots. These are sometimes highly experimental green coffees made for a boutique market.

These small batches are extremely limited and therefore valuable—perfect for a 1-15 kg roaster. However, the small batch size doesn't necessarily guarantee a perfect roast the first time. Two to three batches are usually needed to create a roast profile, sometimes more.

Limiting creativity due to one’s own size

Meso and macro roasters simply can't roast such small batches because their roasting equipment is designed for a larger capacity. Large roasting equipment must be loaded to at least 70% of its maximum capacity. Larger roasters can't afford to create a few roast profiles for premium coffees or try something they've never done before. Cost of goods prohibits it—and who wants to experiment with 140 kg of green coffee?

Due to their size, large roasters therefore focus on green coffees that are cheaper and often less sensorially distinctive. They need coffees with a stable profile and available in large quantities. This approach defines the entire supply chain differently than a small roaster would: megalots instead of microlots, containers instead of jute sacks, stable profiles instead of surprises.

In practical terms, the large roasters limit themselves by their size when it comes to roasting sensorially complex coffees, experimenting, and making great leaps forward. However, many small roasters also limit themselves by communicating the roasting craft but then roasting the same green coffees as the big players.

Flavio from Birchbach Coffee (ZVG: Flavio Lissandrello)

Flavio from Birchbach Coffee (ZVG: Flavio Lissandrello)

But Flavio Lissandrello from Birchbach Coffee doesn't believe that small roasters make everything better.

"In my opinion, the opposite is often true. Unfortunately, small roasters often do things worse than the larger ones due to inexperience, lack of funds, and lack of technology. Yes, in my opinion, there are also good large ones."

Flavio Lissandrello

Mirjam Baumgartner from Bühler also often sees that the large roasteries are often more professionally equipped.

The disadvantage of large roasters is often that the raw material for their popular products must be available in large quantities. On the other hand, large roasters are often more professional in terms of coffee knowledge and understanding and can afford better equipment. For example, small roasters are usually limited to drum roasting technology, as they don't have the opportunity to use other technologies. Large roasters can utilize more advanced technologies in many respects (e.g., a variety of roasting profiles, auto-corrective profile roasting systems, green coffee preheating, etc.). But, as always, there are exceptions.

Mirjam Baumgartner

Knud Buck of Röststube Lübeck confirms this. "Sometimes there's more human error than I'd like." Knud roasts coffee mainly for himself on a 1kg Giesen roaster.

Knud's informative Instagram account

Knud's informative Instagram account

However, he also sees the fallibility of roasting as an advantage:

"Since I roast only for myself, I'm not dependent on reproducibility. I don't have a customer base that relies on the same coffee taste every time. This gives me the freedom to experiment again and again. Essentially, no two roasts are the same. Although I do practice re-roasting particularly successful roasts."

Knud Buck

Experimenting on a very small scale is possible, but again, with a batch size of 150 kg and more, the reason for an experiment has to be really good.

Really nasty coffee from the big ones

Large companies can produce coffee cheaply and target low-price markets – and these markets are huge. But the size of a roastery itself doesn't determine whether it purchases clean (defect-free) coffee. It all depends on the approach and the understanding of quality.

Nespresso, which probably roasts well over 100,000 tons per year, doesn't buy defective coffee—it contradicts its promise of quality and brand messaging. Others, however, who roast far less but want to target low-price markets, certainly resort to coffee of inferior sensory quality.

For those who "just need a coffee" or, even better, "a caffeine boost," quality isn't a deciding factor. And the coffee quality reflects that perfectly; you get what you pay for .

Cheap green coffee is often poorly sorted, with a lot of broken coffee, etc., while better green coffee also costs more. The equation is simple. So, if you're determined to pay less for coffee, you'll get the rejects. And yes, sometimes you'll find qualities that even a layperson would visually classify as poor coffee. Only, this coffee doesn't come in bean form, but ground, as instant coffee, or in pre-portioned units.

I've never heard of a small roaster successfully selling nasty coffee. That roaster would probably disappear quickly. The truly nasty flavors can be found at the very large roasters targeting the low-price markets—but let's be honest: who would seriously expect the best quality at the lowest prices?

One Size Fits All – Roasting Profiles

So if we assume that the very large roasters roast cheap green coffee and do so as efficiently as possible, i.e. a lot of coffee in a short time, then the optimal, finely tuned profile is not being used.

Typically, these are one-size-fits-all profiles that roast the coffee for the same time, but at a different or lower final temperature (= lighter or darker). This often results in inexpensive coffee from large roasters being roasted significantly darker. The deep roast can mask defects and smooth out differences.

But large roasters, of course, also roast light coffees, which are often the "mild" and "harmonious" ones. The depth of roast, or also called the degree of roast, often marks the greater difference between the coffees of the very large roasters than completely different blends. The same blends are also often roasted lighter or darker to create a unique product.

The roasted products of the very large roasters are more standardized, sensorially undemanding, but extremely consistent coffees that serve the purpose for the vast majority.

And large roasters have the tricky task of tasting coffees precisely, blending them themselves, or having them blended, so that they always taste the same. This is sensorially monotonous, but no less challenging than tasting the most complex of all coffees.

Let's get down to business – who's roasting how? Small and large in conversation

It's astonishing how many people talk about a "roasting secret"—the special way green beans are browned. I was equally astonished that the major roasters, in particular, spoke openly about their coffee roasting methods. Many also saw it as a window into dispelling the rumors about "800°C and two minutes." We asked both small and large companies.

Nano Roastery

How does Röststube Lübeck roast?

Knud Buck is probably the closest thing to a nano-roaster. Anyone who follows his Instagram channel can see how meticulously Knud strives to perfect every parameter of roasting, as well as preparation. It's a veritable laboratory. He roasts on a 1kg Giesen roaster, with batches of 750g.

“This amount is easy to control and I can do twice as many roasts, thus gaining twice as much experience, as if I always chose the maximum batch,” says Knud.

Intentionally underfilling the roasting drum can drastically reduce roasting time. However, the small roasting drum also has its weaknesses, says Knud. "Larger roasting systems have a greater thermal mass due to their design, which, at least theoretically, could provide more stability during the roasting process."

For him, roasting coffee is a hobby, but one that he pursues with more precision than most small roasters.

"I associate small roasters with craftsmanship, with more love, with more dedication, and ultimately with better quality in the cup. But that's not always true!"

Knud Buck

Knud's roasting times range from 7 to 15 minutes, with maximum bean temperatures of 205°C. These temperature specifications should always be treated with caution, as they are not comparable.

Like many other roasters I interviewed in a Facebook survey, Knud roasts after the first crack and the development time.

"For most filter roasts, I try to reach first crack (FC) after 9 minutes and allow for a development time of between 12 and 18% from there, depending on the coffee. Another indicator is the temperature development from FC to final roast temperature; my range here is from +4°C for light filter roasts to +10°C for espressos. I don't roast darker."

The Rate of Rise is also crucial for Knud: "Especially when exchanging ideas with other roasters and discussing roasting profiles, the Rate of Rise is much more meaningful than comparing absolute temperatures. For me, the Rate of Rise is the decisive factor for evaluating roasting profiles."

Micro-roastery

How do coffee makers roast?

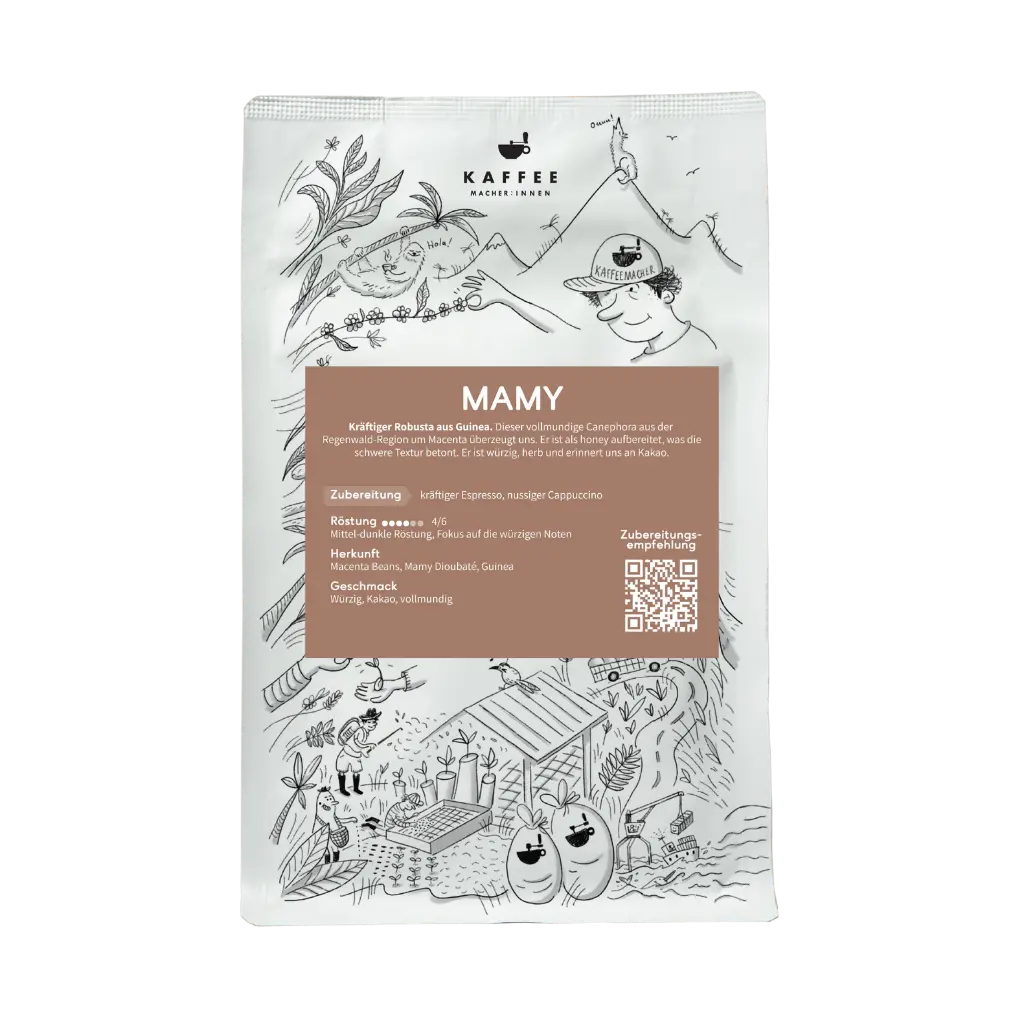

Our roasting philosophy is strongly linked to the green coffees we purchase. We tend to use heavier coffees for espresso, and we roast floral and fruity coffees more for filter coffees.

Yellow: Filter coffee, Red: Specialty Espresso, Blue: APAS

Yellow: Filter coffee, Red: Specialty Espresso, Blue: APAS

We treat each coffee slightly differently. Not because we simply want to, but because the coffee itself demands it. A coffee from Brazil from the APAS cooperative, for example, behaves differently in the roasting drum than a coffee from our Finca Santa Rita in Nicaragua.

If we had a roasting dogma, it would probably look like this:

- we roast for the respective purpose, because

- We differentiate between filter, espresso and coffee crème roasts

- We roast as much as necessary and as little as possible, because

- we like coffees with intensity of aromas, with a soft mouthfeel and character

We fill the 12 kg drum with 4-5 kg for filter coffee, 8-11 kg for specialty espresso, and 12 kg for slightly more mature espressos. Fully loading the drum requires a different amount of gas than a less full drum. This also extends roasting times.

We roast using Cropster's roasting software, analyzing our roasting process live. We follow our own roasting curves, ensuring that the roasts – theoretically – taste the same. We also taste the batches and can thus compare the coffee sensorially with the roasting curve.

Over the time a green coffee is in our warehouse, it's quite possible that we'll adjust the roasting profile several times. If we receive a coffee in midsummer and roast it until Christmas, we have to adjust the profile according to the outside temperature. This keeps roasting coffee never boring.

Meso Roastery

How does Rast roast coffee?

Beatrice Rast from the Rast coffee roastery wrote me the following lines.

"I generally find it difficult to make judgmental distinctions between large and small; we prefer to leave the assessment (including about manufacturing/industry) to the customer and concentrate on our work, i.e. we prefer to focus on ourselves and have the incentive to constantly develop and convince the customer of our work, our coffee, service and quality.

We roast in Ebikon using Probat drum roasters, which come in various sizes (5, 12, 45, and 90 kg). This gives us great flexibility and allows us to better meet our customers' needs and guarantee our roasted freshness. The roasted coffee is cooled by air on all machines.

Our roasting times and temperatures vary depending on the machine, the green coffee, and the roasting profile. We typically roast for around 15–20 minutes. Since we offer everything from light to medium to dark, the final temperatures naturally vary greatly and will vary accordingly.

Because our roasting time tends to be long, a lot of chlorogenic acid can be broken down, which makes the coffee more digestible, but of course, due to the high time required, it is also more costly.

Roasting is carried out according to roasting profiles, timing, color, and final and development times developed by us. When purchasing green coffee or materials, we strive for long-term partnerships and want to maintain close relationships with our partners."

Macro Roastery

How does Hochstrasser roast in Lucerne?

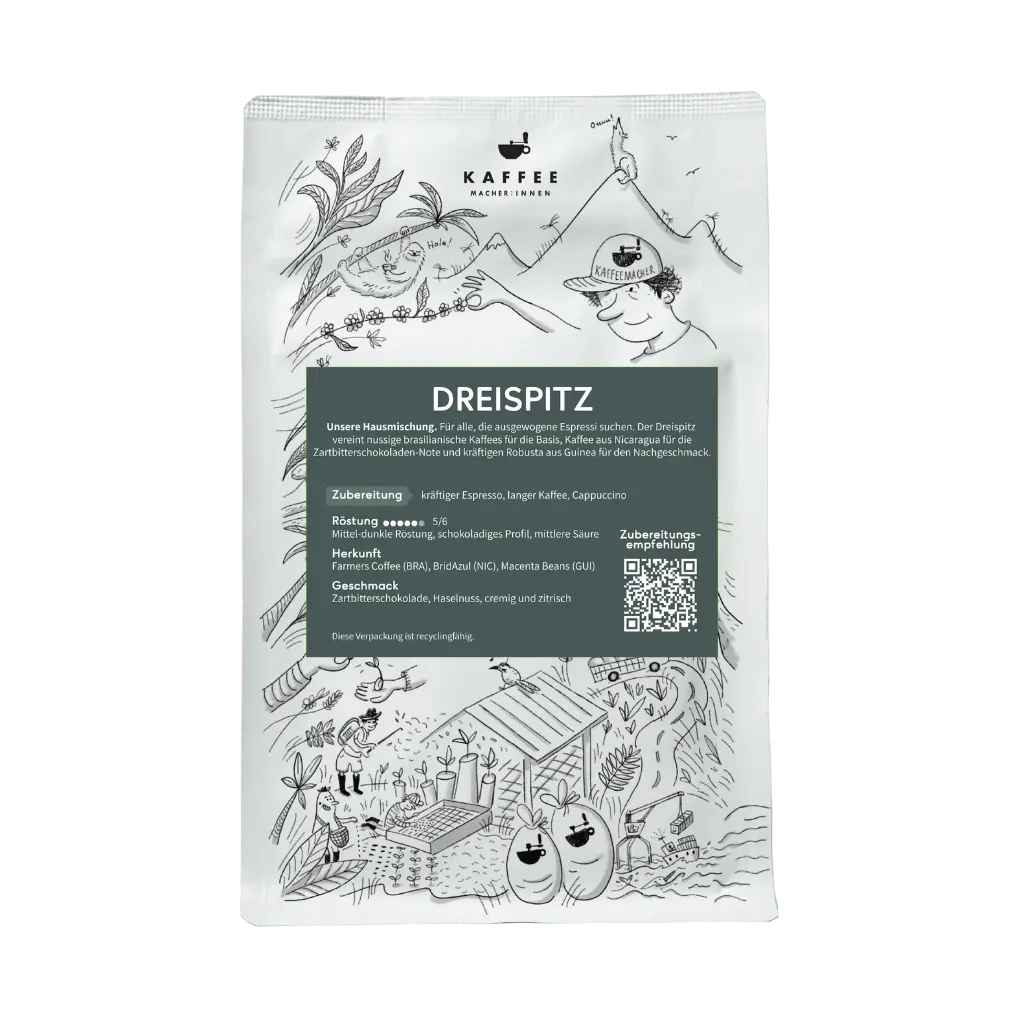

At Hochstrasser AG coffee roastery in Lucerne, I spoke with Production Manager Kevin Heer and Master Roaster Andy Strittmatter. Hochstrasser is one of the ten largest roasters in Switzerland and roasts approximately 1,500 tons of coffee annually.

With four roasting systems (5 kg, 60 kg, 120 kg, and 240 kg), Hochstrasser can meet a wide variety of needs. The company has long since moved beyond roasting for its own purposes, but also fulfills a wide variety of private label requests.

The larger the roaster, the more important private labeling becomes – it helps the roaster utilize its large capacities efficiently. It is also attractive for private label customers, as it allows for consistent and cost-effective coffee production.

Kevin Heer says: "We roast exclusively with drum roasters from industry leader Probat. Furthermore, we are very efficient and can handle large orders with high quality, and we are also flexible enough to handle smaller orders."

Probat's largest drum roaster is almost the size of a small truck. Including the peripheral equipment, the exhaust and supply air ducts, the lines for transporting roasted coffee, and the afterburner, the system takes up the space of a small single-family home.

With the drum roaster, roasting times also increase. Hochstrasser roasts between 13 and 17 minutes, which is very similar to how we coffee makers roast. The roastmasters at Hochstrasser also monitor the roasting process on a monitor, but this monitor is located next to the roaster. This allows for physical proximity to the roaster, especially when special orders need to be roasted according to key points like the first or second crack. These are marked manually by the roasters.

The roasting temperatures (the hot air flow temperature) are between 230 and 250 degrees Celsius. The larger systems offer several advantages, according to Heer:

“With large roasting systems, you have much greater consistency, also due to the many adjustment options of the system.”

Regarding gentle long-term roasting, Heer emphasizes that the energy supply to the beans is more gentle when they are heated using a lot of hot air, rather than directly through the contact heat of the drum.

Large roasters like Hochstrasser partially quench the coffee, “but only with enough water so that the roasted coffee doesn’t absorb any water,” says Heer.

"From our perspective, quality is defined by the roasting time, and the roasting curve by the roasting system. If all these factors are right, it's possible to achieve greater consistency with a larger roasting system. Other important factors for us are the raw coffee quality, the quality controls of the raw and roasted coffee (via cuppings), and subsequent optimal packaging to protect the roasted coffee."

Mega roastery

How does Melitta roast?

I also had an interesting conversation with Melitta's production management. They were very open about the roasting information. Later, my text, which I had written based on an interview, was revised again and adapted to the company's guidelines. The result is a text based on my own, but subsequently modified.

Approved text by Melitta

In a conversation with Dörte Lämmerhirt (Head of Production in Melitta's Coffee Division), it became clear that they are also focusing on developments in the specialty and small-scale roaster segment.

Melitta roasts on various roasters, including drum and chamber roasters. Batch sizes can range up to 10 bags of coffee.

Anyone who roasts very large quantities of coffee needs large batches, that's clear. According to Lämmerhirt, this doesn't come at the expense of roasting time: "We don't pursue high-yield roasts of just a few minutes—and I've been on board for almost a decade." Melitta's roasting times range from seven to 20 minutes—depending on the variety and coffee segment. For example, dark espressos require a very long roasting time.

"Nothing like two minutes at 800 degrees." Lämmerhirt emphasizes that good coffee takes time. Melitta roasts primarily based on roast color and final temperature. The roasting systems are operated from a central control center, from where the coffee roasting profiles are precisely controlled.

Large machines allow Melitta to roast coffee very consistently and with consistently high quality. "This also has to do with the high quality expectations our consumers have of our products, which we meet every time." Human error is virtually zero, as much is automated. "We talk a lot about coffee," says Lämmerhirt, "and it's not always the same." Green coffee is a natural product that, despite specifications, doesn't have standardized and consistent properties. "At Melitta, we adapt our roasting profiles to each individual green coffee."

Roasting itself is an important topic, not just for large roasters, says Lämmerhirt. Roasting is generally an expression of the high quality that Melitta has pursued for over 111 years. However, it's also clear that the concept of handcrafted coffees and specialty coffees are increasingly triggering positive reactions among consumers.

However, this is a generalization: “There are excellent roasts and bad roasts – among the very small and the very large.”

How does Delica roast coffee?

Delica is also familiar with the arguments and claims of other roasters that the big players don't roast well. Nicole Gisi, project manager, former roasting master, and author of the book "Coffee. Pleasure-Passion-Science," says:

"We're above that because we know the truth. Ultimately, everyone is confident they're doing the right thing. At Delica AG, we're proud that our roasting processes are on par with commercial roasters. It's not the size of the roastery, but rather the experience, the roasting process, and the quality of the green coffee, as well as the grinding and extraction methods, that make good coffee."

Gisi goes on to say that small and large are neither good nor bad: “In my opinion, there are neither advantages nor disadvantages, because you have to adapt to the situation and take appropriate precautions.”

Gisi and her team roast on tangential and centrifugal roasters. Batch sizes range from 140 to 500 kg, and they roast approximately 17,000 tons of coffee annually.

She doesn't believe in the 2 minutes and 800° claims – “we roast for at least 7 minutes, the longest roasting times are 20 minutes”.

Regarding the gentle, long-term roasting process, Gisi makes it clear that this is not about quality, but rather about marketing a roasting style:

“These are marketing statements, with little information about quality.

Nicole Gisi on gentle long-term roasting

Of course, there are parameters regarding roasting time that indicate high quality. "Hand-roasted" is not a quality feature for me. The roaster stands next to the roaster and finishes the roasting manually. Depending on experience, lighting conditions, and the roaster's mood on the day, the roasts will taste and smell different, as the process is not standardized. This is also a philosophy, but if the customer always expects the same result, standardization of the process is necessary. (Craftsmanship involves people and thus increases the risk of errors. The higher the degree of automation, the fewer surprises—but also the less courage).

“We try to keep the error rate as low as possible at all stages so that the consumer receives stable end products.”

Gisi spoke extensively on the subject of chlorogenic acid.

"Chlorogenic acid is a group of esters of hydroxycinnamic acid and quinic acid. Chlorogenic acid and its degradation products contribute significantly to the flavor and aroma, as well as the color, of coffee. Because chlorogenic acid is thermally unstable, it is hydrolyzed during the roasting process to quinic acid and caffeic acid. With deep roasts, almost complete degradation to various phenolic compounds can occur. Their degradation products can be acidic and astringent. With incomplete or very light roasting, larger amounts of chlorogenic acid remain in the bean. It can cause intolerance and stomach upset in sensitive individuals."

How does Aldi roast?

In a conversation with Michael Körnig from NewCoffee GmbH , the Aldi coffee roastery, I also learned a lot about the recent history of large-scale roasting.

But first I wanted to know what his opinion is on smaller roasters.

"I'm always happy when I discover special microlots from small specialty roasters. These small roasteries have opportunities that we, as a large company, don't have. They can bring out the flavor details and are certainly an asset to the coffee landscape."

Michael Körnig, NewCoffee GmbH

Körnig made it clear, like few others, that it is primarily technical differences that allow for or disallow special features. He didn't attempt to argue this away, but rather explored the possibilities.

"I see a lot of good in small roasteries, but we large companies also have our advantages. However, purchasing microlots is not possible for us, as we cannot process even small quantities. We need coffee quantities sufficient to supply around 1,940 stores."

In stark contrast, we, as a coffee maker, just purchased a 70kg Nanolot. We'll do about three test roasts of this and then sell another 55kg – it's worthwhile for us, as we roast filter coffee in 5kg batches. For any larger roaster, this quickly becomes complicated, if not impossible.

While it's difficult for NewCoffee to process small batches, the use of different profiles is possible. "Our business model is simply different." He sees the leverage of the larger companies primarily in the degree of automation in packaging: "Among other things, we can package more cost-effectively. This reduces labor costs and enables us to offer high-quality coffees at reasonable prices."

NewCoffee roasts for ALDI and other external customers at two locations – in Ketsch and Mülheim an der Ruhr.

When it comes to roasting times, NewCoffee differentiates between ground coffees and coffees for coffee pods, which take between 6 and 9 minutes, and bean coffees, which are usually roasted for 12 minutes and, in exceptional cases, even 15 minutes. For large roasters, these are times you probably wouldn't have imagined.

Körnig commented: "One reason for longer roasting times, especially for ground coffees, was the acrylamide problem. If the roasting time is too short, the acrylamide level would be too high. That's why our roasting time is never less than six minutes."

Körnig, like Gisi regarding chlorogenic acid, provides concrete facts on topics that large roasters are repeatedly asked about. Smaller and medium-sized roasters are significantly less likely to be affected by tests and samples for acrylamide, furan, OTA, and residues in coffee—although all four topics cannot be ruled out.

Körnig also speaks precisely about the "high-yield process" – "We've never done that." According to internet research, coffee was roasted in 90 seconds using this process. The coffee's volume increased significantly more than usual, the density was low, and suddenly 400g of roasted coffee took up the space of 500g of roasted coffee. You can read about this in a 1984 article from Der Spiegel .

So there's something to the 90-second roast after all—but the question is, is it still true today? I'm convinced, but I haven't gotten to the roasters yet.

Körnig takes a differentiated view of the “gentle long-term roasting”:

"What is gentle? Long-term roasting brings a different flavor profile, but it also breaks down acids—both unwanted and desired. Coffee often tastes simply baked."

Michael Körnig

Körnig also commented on chlorogenic acid: "Chlorogenic acids are present in coffees, but especially in very short roasts. Since we roast for at least six minutes, the problem hardly arises for us. But we roast 90 percent Arabica and hardly any Robusta – and since the proportion of chlorogenic acid in Robusta is significantly higher than in Arabica, it doesn't affect us as much."

How does UCC Switzerland roast?

UCC, the Ueshima Coffee Company from Japan, roasts in Zollikofen near Bern, Switzerland. UCC roasts a lot of private label coffee, and major Swiss retailers are among its largest customers. Benjamin Schütz from UCC spoke with me about their roasting style.

Schütz sees the advantage of large roasting plants in their consistency. "We define 12 to 13 key points in a profile, and the roaster follows them, come what may." UCC roasts on two roasters from Lilla in Brazil, each with a capacity of 500 kg.

Batch sizes range between 400 and 500 kg. The Lillas are drum roasters, which are different systems than those we've encountered at Aldi, Delica, or Melitta. Drum roasters are less efficient than convection systems, and therefore roasting times are significantly longer on average: a roast at UCC takes between 12 and 16 minutes.

Such large drum roasters work because some of the hot exhaust air is recycled and fed back into the system. This eliminates the need to heat up this "new" air. If only fresh air were drawn in, rapid roasting with such a machine would be impossible.

UCC roasts four to five batches per hour, which amounts to a good 7,000 tons of roasted coffee per year. In addition to the roastmaster, about four other people work on a shift, taking care of downstream processes such as grinding and packaging.

The roasting cycles are very fast, meaning the time between batches is very short. The roaster is empty for only about 10 seconds before new green coffee is added.

UCC then roasts to the desired color, which they use to determine the end of the roast. Here, too, the first crack, development time, and rate of rise are irrelevant. This is quite different from roasters with smaller systems, where these guidelines are used much more frequently.

Schütz is less than diplomatic about the gentle, slow roasting process. "It's like slow cooking. But with meat, it tastes better." He has to chuckle when asked what he thinks about the statement that coffee is "roasted by hand." "Yes, roasting machines can be operated by hand. But that's about it."

Like many larger roasters, UCC also quenches the roasted coffee with water immediately after it leaves the roasting drum. 70 to 74 liters are needed for a 500 kg batch of coffee, which results in approximately 3-3.5% residual moisture in the beans. Quenching takes place in the drum after the specified final temperature has been reached.

Like Gisi, Schütz has a scientific background and welcomes the chlorogenic acid discussion.

"The stomach must be able to absorb acids; that's its function. When acid comes in, it has to absorb it with alkalis. But if it's already over-acidic, for example, due to animal proteins, then the body has much more difficulty processing acidic foods. This can lead to heartburn."

Benjamin Schütz, UCC Switzerland

For Schütz, it's clear that chlorogenic acids alone aren't harmful to the stomach, but that the overall diet determines the absorption capacity of coffee. And, of course, whether sugar is added to the coffee also has an influence. More sugar means more acid in the stomach.

Comparison table: Who roasts coffee like this?

We extracted the information from the interviews and arranged it in a table for comparison.

| Nano | Nano | Micro | Meso | macro | Mega | Mega | Mega | Mega | |

| Roasting room Lübeck |

Birchbach Coffee |

coffee maker | Rest | Hochstrasser | UCC Switzerland | Delica AG | Aldi / NewCoffee GmbH |

Melitta | |

| Roasted quantity per year in tonnes | <1 | 3 | 26 | n/a | 1500 | 7000 | 17000 | n/a | n/a |

| Number Roasting machines |

1 | 1 | 1 | 4 | 4 | 2 | 3 | n/a | n/a |

| Batch size min. | 0.7 |

1 | 4 | 5 | 230 | 420 | 140 | n/a | n/a |

| Batch size max. | 0.7 | 1 | 12 | 90 | 280 | 500 | 500 | n/a | 650 |

| Roasting time min. | 7:00 | 8:30 | 9:00 | 15 | 13 | 10:30 | 07:00 | 06:00 | 07:00 |

| Roasting time max. | 3:00 PM | 10:00 | 4:30 PM | 20 | 17 | 3:00 PM | 8:00 PM | 3:00 PM | 8:00 PM |

| Definition Roasting | |||||||||

| Time | x | x | x | x | x | x | |||

| Final temperature | x | x | x | x | x | x | x | x | |

| Color | x | x | x | x | x | x | |||

| Priority at Roasting philosophy |

|||||||||

| 1. Crack | 1 | 3 | 1 | 1 | |||||

| 2. Crack | 3 | ||||||||

| RoR (Rate of Rise) | 1 | 1 | 1 | ||||||

| Final temperature | 1 | 1 | 1 | 1 | 1 | 1 | |||

| Development time | 1 | 2 | 1 | 1 | |||||

| Roast color | 4 | 2 | 1 | 1 | 1 | 1 | 1 |

Who roasts after the first crack, rate of rise, development time, final temperature…

The roasting stages are measured differently by roasters. In a Facebook survey, the vast majority of specialty and small roasters told me the following order:

The “total roasting time” did not receive a single vote in the roaster forum, and the final temperature only received three.

This clearly distinguishes them from large roasters: from a certain roasting size (meso- and above), roasting is generally based on roasting time, final temperature, and roast color. The first crack, development time, and rate of rise play a minor role, if any. The opposite is true for nano- and micro-roasteries, which are physically closer to the roaster, listen to the first crack, mark it, and then derive the development time.

Mirjam Baumgartner from Bühler confirms these findings:

In my experience, only small, manual operations focus on the first and second crack in their daily production. These operations roast with considerable expertise and attention from the roastmaster.

At a large roastery, the first and second cracks are naturally discussed when developing a new roast, but it's inconceivable that a roastmaster observes these parameters exactly for every roast. In this case, they rely on the roaster's reproducibility and, in most cases, break off based on temperature. This can certainly be the case at smaller roasteries as well.

In other words: If the roasting machine has the temperature under control, the first crack and the second crack always occur at exactly the same time. In this case, the roastmaster of a large-scale facility no longer needs to pay attention to the cracking process.

And now? Where are we headed?

Large roasteries are getting bigger

It's becoming apparent every few weeks: large roasters are getting even bigger, and roasting machine manufacturers are also feeling the effects. Baumgartner again:

Bühler's core competency as a mechanical engineering company is plant engineering, which is why the Infinity Roast is our flagship roaster. It comes in 180 kg, 360 kg, or 540 kg batch sizes and offers complete flexibility and reproducibility through a variable air-to-bean ratio and auto-corrective profile roasting. Our largest plant in the USA, with two Infinity Roasts, produces around 6 t/h in continuous operation, but we have large roasting companies worldwide as customers.

Our proposed classification into five categories: nano, micro, meso, macro, mega, will soon be supplemented by “giga” – and this already applies to certain roasters.

There are more and more small roasteries

At the same time, there's a countertrend: that of nano- and micro-roasteries. It will be exciting to see how large nano-roasteries become, whether micro-roasteries limit their growth, become meso-roasteries, or even merge with another micro-roaster. We maintain a current collection of coffee roasters in Switzerland , and Quijote Kaffee maintains a collection of roasters in Germany .

The coffee quality is improving

Drinking coffee outside is becoming more and more enjoyable. In general, the coffee offerings are becoming more diverse—and we're not talking about beverage categories, but rather the flavor profiles consumers can access today.

More and more nano- and micro-roasteries are focusing entirely on specialty coffee. For reasons discussed in detail, these smaller roasters may have a different focus than larger ones.

The big ones act small

Jacobs and Dallmayr have shown the way, and others will follow. Large roasters are increasingly focusing on smaller projects, on smaller roasteries that are designed to open up a segment they otherwise can't reach. The big players have understood that the handcrafted concept isn't pure marketing, but rather a truly authentic message that, for many consumers, triggers the feeling of holding something authentic in their hands. Beautiful brochures and campaigns don't help – for many, the smaller is simply more authentic.

The question remains how credible the small-scale projects of the large roasters will be. It won't be a lack of know-how, access to green coffee, or roasting expertise that will be a problem – however, I see limited acceptance among a specialty coffee-oriented audience. For many, the big name will likely still trump the presentation. I'm curious to see who will separate the product from the name.

We all learn – together

I'll continue to add to these roasting articles. More producers and roasters will be added. Perhaps some roasters will also be willing to contribute roast profiles.